Content Menu

● Understanding Vibrating Sieves

>> What is a Vibrating Sieve?

>> How Do Vibrating Sieves Work?

● Key Features of Top-Rated Vibrating Sieves

>> 1. Material Construction

>> 2. Vibration Mechanism

>> 3. Screen Size and Mesh Type

>> 4. Adjustable Vibration Settings

>> 5. Ease of Cleaning and Maintenance

● Top Vibrating Sieve Models

>> 1. Dynamic Screener™

>> 2. Ranger Separator™

>> 3. GyraSift™

>> 4. Russell Compact Sieve®

>> 5. Virto-Cuccolini VP2 Vibrating Sieve

● Applications of Vibrating Sieves

>> 1. Food Industry

>> 2. Pharmaceuticals

>> 3. Chemical Manufacturing

>> 4. Mining and Minerals

>> 5. Recycling

● Benefits of Using Vibrating Sieves

>> 1. Increased Efficiency

>> 2. Improved Product Quality

>> 3. Versatility

>> 4. Cost-Effectiveness

>> 5. Ease of Use

● Conclusion

>> Frequently Asked Questions

Vibrating sieves are essential tools in various industries for the efficient separation of fine powders. They utilize vibration to facilitate the movement of materials through a mesh screen, allowing for the effective separation of particles based on size. This article explores the top-rated vibrating sieve models available today, their features, applications, and benefits, providing a comprehensive guide for those looking to invest in this technology.

Understanding Vibrating Sieves

What is a Vibrating Sieve?

A vibrating sieve is a mechanical device that uses vibration to separate materials based on their size. It consists of a screen or mesh that allows smaller particles to pass through while larger particles are retained. The vibration helps to keep the material in motion, preventing clogging and ensuring efficient separation.

How Do Vibrating Sieves Work?

Vibrating sieves operate by generating a controlled vibration that causes the material to move across the screen. The vibration can be adjusted in terms of frequency and amplitude, allowing for customization based on the specific material being processed. As the material moves, smaller particles fall through the mesh, while larger particles are directed to the side for removal.

Key Features of Top-Rated Vibrating Sieves

When selecting a vibrating sieve, several features should be considered to ensure optimal performance:

1. Material Construction

The construction material of the sieve is crucial for durability and hygiene. Stainless steel is commonly used due to its resistance to corrosion and ease of cleaning, making it ideal for food and pharmaceutical applications.

2. Vibration Mechanism

Different models utilize various vibration mechanisms, including electromagnetic, pneumatic, and mechanical systems. The choice of mechanism affects the efficiency and effectiveness of the separation process.

3. Screen Size and Mesh Type

The size of the screen and the type of mesh used can significantly impact the sieve's performance. Fine mesh screens are essential for separating very small particles, while larger screens are suitable for coarser materials.

4. Adjustable Vibration Settings

The ability to adjust vibration frequency and amplitude allows operators to optimize the separation process for different materials, enhancing efficiency and effectiveness.

5. Ease of Cleaning and Maintenance

A design that facilitates easy cleaning and maintenance is vital, especially in industries where hygiene is a priority. Features such as quick-release clamps and removable screens can save time and effort.

Top Vibrating Sieve Models

1. Dynamic Screener™

The Dynamic Screener™ is known for its ultra-hygienic design, making it ideal for industries such as food, pharmaceuticals, and cosmetics. It effectively removes contaminants from powders, ensuring product quality and safety. Its compact design allows it to fit into existing production lines without requiring significant modifications.

2. Ranger Separator™

This model is highly efficient and integrates multiple vibratory motion patterns to control the material flow on the sieve. It is particularly effective for grading materials into multiple fractions and is widely used in industries such as ceramics, metal powders, and recycling.

3. GyraSift™

The GyraSift™ is designed for high-capacity applications, capable of handling large volumes of material. Its unique design allows for efficient separation of fine powders while minimizing the risk of contamination. This model is suitable for various industries, including food processing and chemical manufacturing.

4. Russell Compact Sieve®

The Russell Compact Sieve® is a versatile solution for removing oversize contamination in bulk powders and liquids. Its compact design makes it ideal for operations with limited space, and it is known for its high capacity and ease of cleaning.

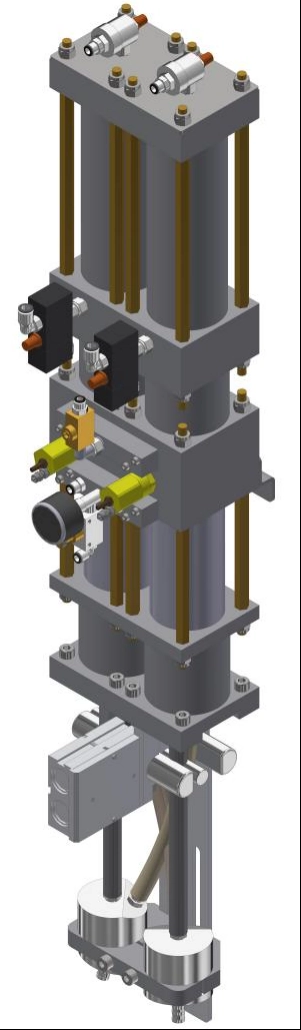

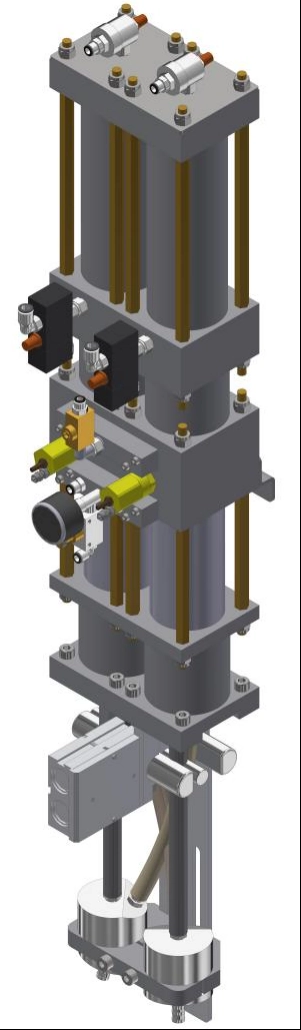

5. Virto-Cuccolini VP2 Vibrating Sieve

This model utilizes innovative multi-frequency sieving technology, enabling precise separation of ultra-fine powders. It is suitable for applications in food, recycling, coatings, and metal powders, making it a versatile choice for various industries.

Applications of Vibrating Sieves

Vibrating sieves are used across a wide range of industries, including:

1. Food Industry

In the food industry, vibrating sieves are used to ensure product quality by removing contaminants and ensuring uniform particle size in powders such as flour, sugar, and spices.

2. Pharmaceuticals

Pharmaceutical companies utilize vibrating sieves to separate active ingredients from excipients, ensuring the purity and effectiveness of medications.

3. Chemical Manufacturing

In chemical manufacturing, vibrating sieves are essential for separating fine powders and granules, ensuring consistent product quality and performance.

4. Mining and Minerals

Vibrating sieves are used in the mining industry to separate valuable minerals from waste materials, enhancing the efficiency of the extraction process.

5. Recycling

In recycling operations, vibrating sieves help separate different materials, such as metals, plastics, and glass, facilitating the recycling process and improving material recovery rates.

Benefits of Using Vibrating Sieves

1. Increased Efficiency

Vibrating sieves enhance the efficiency of the separation process, allowing for faster processing times and higher throughput.

2. Improved Product Quality

By effectively removing contaminants and ensuring uniform particle size, vibrating sieves contribute to improved product quality and consistency.

3. Versatility

With various models available, vibrating sieves can be tailored to meet the specific needs of different industries and applications.

4. Cost-Effectiveness

Investing in a high-quality vibrating sieve can lead to significant cost savings by reducing waste and improving production efficiency.

5. Ease of Use

Most modern vibrating sieves are designed for ease of operation, with user-friendly controls and features that simplify maintenance and cleaning.

Conclusion

Vibrating sieves are indispensable tools in many industries, providing efficient and effective separation of fine powders. With various models available, it is essential to choose the right vibrating sieve based on specific needs and applications. The Dynamic Screener™, Ranger Separator™, GyraSift™, Russell Compact Sieve®, and Virto-Cuccolini VP2 are among the top-rated models that offer exceptional performance and reliability.

Frequently Asked Questions

1. What is the primary function of a vibrating sieve?

- The primary function of a vibrating sieve is to separate materials based on size, allowing smaller particles to pass through while retaining larger ones.

2. What industries commonly use vibrating sieves?

- Vibrating sieves are commonly used in the food, pharmaceutical, chemical, mining, and recycling industries.

3. How do I choose the right vibrating sieve for my application?

- Consider factors such as material type, required separation size, production volume, and hygiene requirements when selecting a vibrating sieve.

4. What maintenance is required for vibrating sieves?

- Regular cleaning, inspection of screens for wear, and checking vibration settings are essential for maintaining optimal performance.

5. Can vibrating sieves handle wet materials?

- Yes, many vibrating sieves are designed to handle both dry and wet materials, but it is essential to choose a model specifically designed for wet applications.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.