Content Menu

● Understanding Powder Coating

>> What is Powder Coating?

>> The Importance of Quality in Powder Coating

● The Role of Vibrating Sieves in Powder Coating

>> What are Vibrating Sieves?

>> How Vibrating Sieves Work

● Benefits of Using Vibrating Sieves in Powder Coating

>> 1. Enhanced Product Quality

>> 2. Increased Efficiency

>> 3. Reduced Downtime

>> 4. Cost Savings

>> 5. Versatility

● Implementing Vibrating Sieve Technology

>> Choosing the Right Vibrating Sieve

>> Maintenance and Best Practices

● Future Trends in Vibrating Sieve Technology

>> Integration with Automation

>> Use of Ultrasonic Technology

>> Sustainability Considerations

● Conclusion

>> Frequently Asked Questions

In the world of powder coating, efficiency and quality are paramount. The introduction of vibrating sieve technology has revolutionized the way manufacturers process powders, ensuring that the final products meet stringent quality standards while optimizing production efficiency. This article delves into how vibrating sieve technology enhances powder coating processes, the benefits it brings, and the future of this technology in the industry.

Understanding Powder Coating

What is Powder Coating?

Powder coating is a finishing process that involves applying a dry powder to a surface, which is then cured under heat to form a hard, protective layer. This method is widely used in various industries, including automotive, appliances, and furniture, due to its durability and aesthetic appeal.

The Importance of Quality in Powder Coating

Quality in powder coating is critical as it directly affects the appearance, durability, and performance of the coated products. Any impurities or inconsistencies in the powder can lead to defects such as uneven finishes, poor adhesion, and reduced corrosion resistance.

The Role of Vibrating Sieves in Powder Coating

What are Vibrating Sieves?

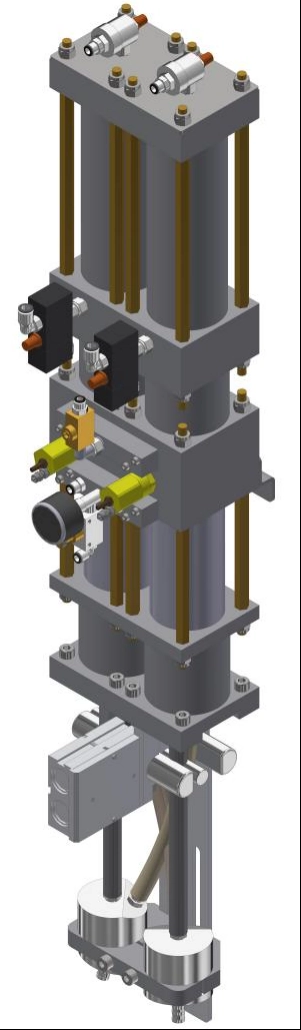

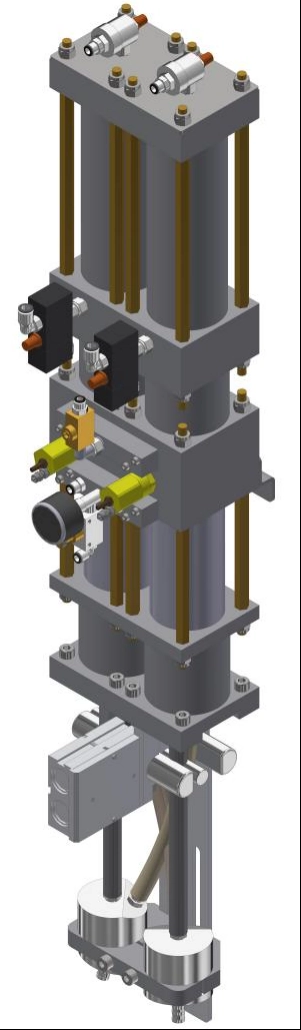

Vibrating sieves are mechanical devices that use vibration to separate materials based on size and density. In the context of powder coating, these machines are essential for ensuring that the powder is free from contaminants and is of uniform particle size.

How Vibrating Sieves Work

Vibrating sieves operate by creating a controlled vibration that causes the powder to move across a mesh screen. As the powder passes through the screen, larger particles and impurities are separated from the desired material. This process can be fine-tuned by adjusting the vibration frequency and amplitude, allowing for precise control over the separation process.

Benefits of Using Vibrating Sieves in Powder Coating

1. Enhanced Product Quality

One of the primary advantages of using vibrating sieves is the significant improvement in product quality. By effectively removing contaminants and ensuring a uniform particle size, manufacturers can achieve better adhesion and smoother finishes. This leads to a more aesthetically pleasing product that meets customer expectations.

2. Increased Efficiency

Vibrating sieves contribute to increased efficiency in powder coating operations. By automating the sieving process, manufacturers can reduce manual labor and minimize the risk of human error. This automation allows for faster production cycles, enabling companies to meet higher demand without compromising quality.

3. Reduced Downtime

Traditional sieving methods often require frequent cleaning and maintenance, leading to increased downtime. Vibrating sieves, on the other hand, are designed for easy cleaning and maintenance, which minimizes interruptions in the production process. This reliability is crucial for maintaining consistent output levels.

4. Cost Savings

By improving the quality of the powder and reducing waste, vibrating sieves can lead to significant cost savings for manufacturers. Higher quality powders result in fewer defects and rework, while efficient sieving processes reduce the amount of material lost during production.

5. Versatility

Vibrating sieves are versatile and can be used for various types of powders, including those with different densities and particle sizes. This adaptability makes them suitable for a wide range of applications within the powder coating industry.

Implementing Vibrating Sieve Technology

Choosing the Right Vibrating Sieve

When selecting a vibrating sieve for powder coating applications, several factors should be considered:

- Mesh Size: The mesh size should be appropriate for the specific powder being processed to ensure effective separation.

- Vibration Frequency: Different powders may require different vibration frequencies for optimal performance.

- Material Construction: The sieve should be made from durable materials that can withstand the rigors of the production environment.

Maintenance and Best Practices

To ensure the longevity and efficiency of vibrating sieves, regular maintenance is essential. This includes:

- Routine Cleaning: Keeping the sieve clean prevents contamination and ensures consistent performance.

- Inspection: Regularly inspecting the sieve for wear and tear can help identify potential issues before they lead to downtime.

- Calibration: Periodically calibrating the vibration settings can optimize the sieving process for different powders.

Future Trends in Vibrating Sieve Technology

Integration with Automation

As industries continue to embrace automation, the integration of vibrating sieves with advanced control systems is becoming more common. This allows for real-time monitoring and adjustments, further enhancing efficiency and product quality.

Use of Ultrasonic Technology

The incorporation of ultrasonic technology into vibrating sieves is another emerging trend. Ultrasonic vibrations can help prevent mesh blinding, ensuring that the sieving process remains efficient even when processing fine powders.

Sustainability Considerations

With increasing focus on sustainability, manufacturers are looking for ways to reduce waste and energy consumption. Vibrating sieves that optimize powder usage and minimize material loss will play a crucial role in achieving these goals.

Conclusion

Vibrating sieve technology has become an indispensable part of the powder coating process, significantly improving efficiency and product quality. As manufacturers continue to seek ways to enhance their operations, the adoption of advanced sieving solutions will likely increase. By investing in vibrating sieves, companies can ensure they remain competitive in a rapidly evolving market.

Frequently Asked Questions

1. What types of powders can be processed with vibrating sieves?

Vibrating sieves can process a wide range of powders, including those used in automotive, appliance, and furniture coatings, as well as fine powders in pharmaceuticals and food industries.

2. How does vibrating sieve technology improve product quality?

By removing contaminants and ensuring uniform particle size, vibrating sieves enhance adhesion and finish quality, leading to better overall product performance.

3. What maintenance is required for vibrating sieves?

Regular cleaning, inspection for wear, and calibration of vibration settings are essential to maintain optimal performance and longevity of the sieves.

4. Can vibrating sieves be automated?

Yes, many modern vibrating sieves can be integrated with automation systems for real-time monitoring and adjustments, improving efficiency.

5. What is the impact of ultrasonic technology on vibrating sieves?

Ultrasonic technology helps prevent mesh blinding, ensuring continuous operation and efficiency, especially when processing fine powders.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.