Content Menu

● Understanding Powder Sieving in Powder Coating

>> The Importance of Sieving for Powder Coating Quality

>> Common Sieving Technologies for Powder Coating

● Vibratory Sieves: Pros and Cons

>> How Vibratory Sieves Work

>> Advantages of Vibratory Sieves

>> Limitations of Vibratory Sieves

● Advanced Powder Sieve Systems: Features and Benefits

>> High-Energy Vibratory Sieves

>>> Key Benefits

>> Rotary Sieves

>>> Advantages

>> Ultrasonic Sieves

>>> Benefits

● Comparing Powder Sieve Systems and Vibratory Sieves

● Impact on Powder Coating Quality and Efficiency

>> Surface Smoothness and Film Quality

>> Productivity and Cost Efficiency

>> Environmental and Safety Considerations

● Conclusion: Is Our Powder Sieve System Better Than Vibratory Sieves?

● Frequently Asked Questions

Powder coating is a highly specialized finishing process that demands precise control over powder particle size and purity to achieve smooth, durable, and aesthetically pleasing finishes. A critical step in this process is sieving, which removes contaminants, oversized particles, and agglomerates from the powder before application. Among the various sieving technologies available, vibratory sieves have traditionally been popular due to their simplicity and cost-effectiveness. However, newer powder sieve systems, including rotary, ultrasonic, and advanced vibratory designs, have emerged, promising enhanced performance and efficiency.

This article explores whether modern powder sieve systems outperform traditional vibratory sieves in powder coating applications. We will examine the technical features, operational benefits, and limitations of each system to provide a comprehensive comparison.

Understanding Powder Sieving in Powder Coating

The Importance of Sieving for Powder Coating Quality

Sieving is essential in powder coating to ensure uniform particle size distribution and to remove impurities that can affect the coating's appearance and performance. Proper sieving helps maintain powder flowability, prevents clogging in spray equipment, and results in a consistent film thickness and smooth surface finish.

The powder coating process typically involves micronizing raw materials into fine particles, followed by classification and sieving to separate acceptable particles from oversized or contaminated material. The final sieving stage is critical for quality control before the powder is filled into containers or fed into coating equipment.

Common Sieving Technologies for Powder Coating

Several sieving technologies are used in powder coating, including:

- Vibratory Sieves: Use mechanical vibration to pass powder through a mesh screen. They are relatively low cost and suitable for batch operations.

- Rotary Sieves: Employ a rotating mesh screen with air exhaust to remove dust and contaminants, often used in continuous processing.

- Ultrasonic Sieves: Utilize ultrasonic frequency vibrations to prevent mesh blinding and improve flow, ideal for high-volume or automated systems.

- Advanced Powder Sieve Systems: Incorporate high-energy vibratory or other innovative mechanisms to enhance throughput, reduce downtime, and maintain powder quality.

Vibratory Sieves: Pros and Cons

How Vibratory Sieves Work

Vibratory sieves operate by vibrating a mesh screen, causing powder particles smaller than the mesh size to pass through while larger particles remain on top. These sieves are often manually operated and favored for their simplicity and affordability.

Advantages of Vibratory Sieves

- Cost-Effective: Lower initial investment compared to more complex systems.

- Ease of Use: Simple operation and maintenance.

- Suitable for Batch Processing: Ideal for small-scale or intermittent sieving needs.

- Durability: Brands like Husker Finishing Equipment offer robust designs for long-term use.

Limitations of Vibratory Sieves

- Lower Throughput: Manual or semi-automatic operation limits processing speed.

- Mesh Blinding: Fine powders tend to clog the mesh, reducing efficiency.

- Inconsistent Particle Size Control: Less precise than advanced systems, potentially affecting coating smoothness.

- Higher Downtime: Requires more frequent cleaning and maintenance.

Advanced Powder Sieve Systems: Features and Benefits

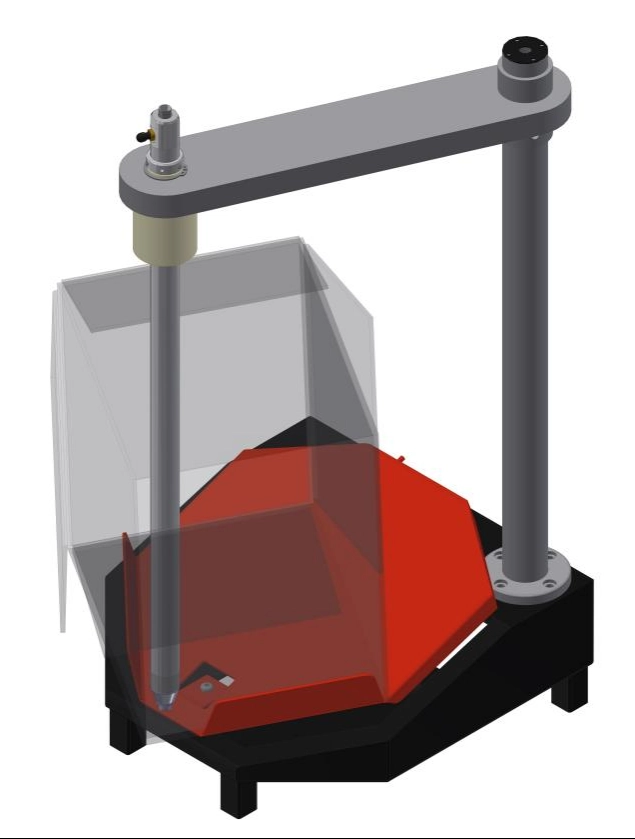

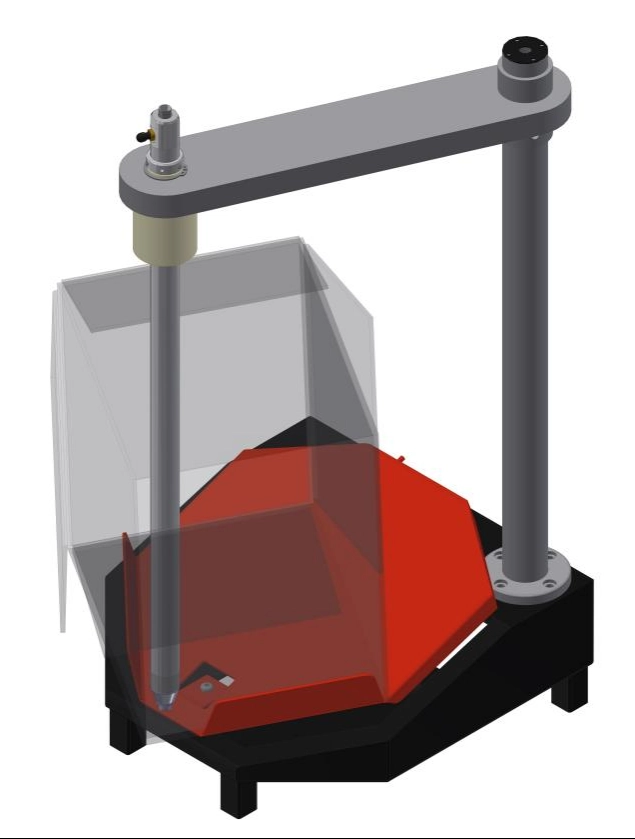

High-Energy Vibratory Sieves

Modern high-energy vibratory sieves, such as Elcan Industries' Hi-Sifter, address many limitations of traditional vibratory sieves. They use intense vibrations to prevent mesh blinding and maintain a free-flowing powder, enabling precise particle size control down to 5 microns.

Key Benefits

- Mesh Blinding Prevention: High-energy vibrations keep the mesh clear, ensuring consistent throughput.

- Precise Particle Size Control: Uniform particle distribution enhances coating quality.

- High Throughput: Capable of processing large volumes efficiently.

- Reduced Downtime: Durable design minimizes maintenance needs.

Rotary Sieves

Rotary sieves, like the AZO, Kemutec, and Nordson models, are widely used in powder coating for their automatic operation and dust exhaust capabilities. They are well-suited for continuous processing and provide consistent sieving without much manual intervention.

Advantages

- Automatic Operation: Reduces labor requirements.

- Dust Exhaust: Improves working environment by removing airborne dust.

- Low Maintenance: Designed for long-term industrial use.

- Good for Bulk Powders: Handles large volumes with ease.

Ultrasonic Sieves

Ultrasonic sieves use high-frequency vibrations to break surface tension on the mesh, preventing clogging and speeding up color changes. Stainless steel mesh screens replace nylon, improving durability and maintenance.

Benefits

- Friction-Free Sieving: Ultrasonic vibrations keep the mesh clean.

- Maintenance-Free: No moving parts reduce wear and tear.

- Ideal for High Production: Suitable for automated, high-volume operations.

- Faster Color Changes: Reduces downtime during product switches.

Comparing Powder Sieve Systems and Vibratory Sieves

| Feature | Vibratory Sieves | Advanced Powder Sieve Systems (Hi-Sifter, Rotary, Ultrasonic) |

| Operation Mode | Manual or semi-automatic | Automatic or high-energy vibratory |

| Throughput | Moderate to low | High |

| Mesh Blinding Prevention | Limited | Effective (ultrasonic or high-energy vibration) |

| Particle Size Control | Less precise | Highly precise |

| Maintenance Requirements | Frequent cleaning and upkeep | Reduced downtime, low maintenance |

| Suitability for Batch Use | Excellent | Suitable for batch and continuous |

| Cost | Lower initial cost | Higher initial investment, but better ROI |

| Dust Control | Minimal | Integrated dust exhaust and containment |

Impact on Powder Coating Quality and Efficiency

Surface Smoothness and Film Quality

The uniformity of particle size directly affects the smoothness of the powder coating film. Advanced powder sieve systems provide narrower particle size distributions, which are essential for high-gloss and smooth finishes. Starting with a 125-micron screen and adjusting to finer screens (e.g., 100 microns) helps achieve optimal results, something more reliably done with precise sieving technology.

Productivity and Cost Efficiency

Advanced sieve systems reduce downtime through less frequent maintenance and faster processing speeds. Automated or high-energy systems minimize labor costs and powder wastage by efficiently removing contaminants and oversized particles.

Environmental and Safety Considerations

Systems with dust exhaust and enclosed sieving reduce airborne powder particles, improving workplace safety and environmental compliance. Ultrasonic sieves also reduce dust generation due to their friction-free operation.

Conclusion: Is Our Powder Sieve System Better Than Vibratory Sieves?

Modern powder sieve systems, including high-energy vibratory, rotary, and ultrasonic sieves, offer significant advantages over traditional vibratory sieves for powder coating applications. They provide higher throughput, better particle size control, reduced downtime, and improved dust management. These benefits translate into higher quality powder coatings with smoother finishes, increased productivity, and lower operational costs over time.

While vibratory sieves remain a cost-effective choice for small-scale or batch operations, investing in advanced powder sieve technology is advisable for manufacturers aiming to optimize quality and efficiency in powder coating production.

Frequently Asked Questions

Q1: What is the ideal sieve size for powder coating to achieve smooth finishes?

A1: Starting with a 125-micron screen is common, adjusting to 100 microns if smoother finishes are needed. The exact size depends on the resin system and milling conditions.

Q2: How does mesh blinding affect sieving efficiency?

A2: Mesh blinding occurs when fine particles clog the sieve mesh, reducing throughput and causing inconsistent particle sizes. High-energy or ultrasonic sieves prevent this issue.

Q3: Can vibratory sieves be used for high-volume powder coating production?

A3: They are generally better suited for batch operations; high-volume production benefits more from automated or advanced sieve systems.

Q4: What maintenance is required for advanced powder sieve systems?

A4: These systems require less frequent maintenance due to durable designs and features like ultrasonic vibration, which prevent mesh clogging.

Q5: How do rotary sieves improve dust control in powder coating?

A5: Rotary sieves often include dust exhaust systems that remove airborne particles, creating a cleaner and safer working environment.

[1] https://elcanindustries.com/blog_posts/powder-coating-sieves-what-are-the-pros-and-cons-heres-what-you-need-to-know/

[2] https://www.pfonline.com/articles/proper-sieve-size-for-powder-coatings-smooth-results

[3] https://www.russellfinex.com/en/case-studies/powder-coating-sieving-technology/

[4] https://blog.praterindustries.com/sieving-techniques-industrial-sieves-vs.-rotary-sifters

[5] https://ems-powdercoating.com/best-powder-coating-machine/

[6] https://buyritefinishing.com/powder/powder-sieves.php

[7] https://pflaumer.com/the-benefits-and-importance-of-using-molecular-sieve-paste-in-high-performance-coatings/

[8] https://www.powdergun.com/power1.htm

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.