Content Menu

● Understanding the basics: powder hoppers and electrostatic spray guns

● Assessing your material: powder properties that affect matching

● Choosing the right hopper: capacity, material, and features

● Matching hopper type to spray gun technology

● Setup steps: installing and tuning the hopper with your gun

● Troubleshooting common issues

● Maintenance and cleaning practices

● How to optimize transfer efficiency and finish quality

● Safety considerations

● Cost considerations and return on investment

● Best practices for color changes and maintenance cycles

● Proven setup patterns for different production scales

● FAQs

● Conclusion

● FQAS

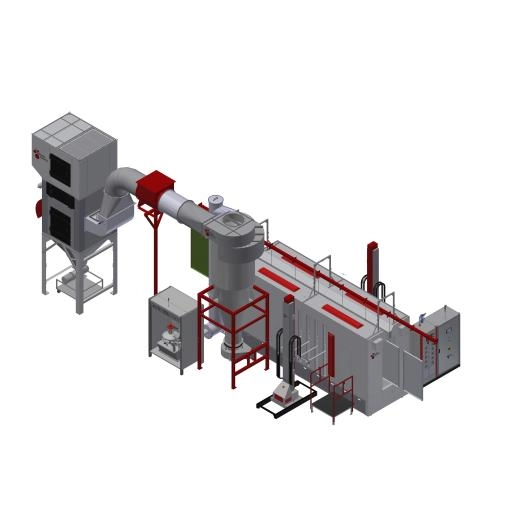

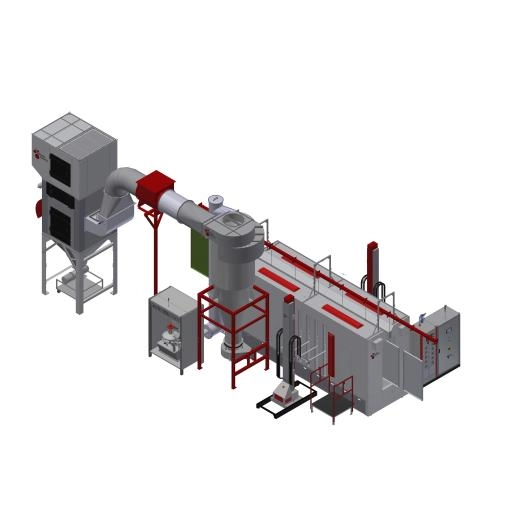

Setting up a powder coating process that is efficient, consistent, and cost-effective starts with proper hardware matching. Among the most critical pairings in this workflow are the powder hopper and the electrostatic spray gun. When these components work in harmony, you enjoy uniform powder distribution, minimal overspray, reduced cycle times, and improved finish quality. This article guides you through best practices for selecting, pairing, and optimizing powder hoppers with electrostatic spray guns, including practical setup steps, common pitfalls, and maintenance tips.

Understanding the basics: powder hoppers and electrostatic spray guns

A powder hopper is the container that holds the powdered coating material before it is fed into the spray gun. It often includes a feed mechanism, agitation system, and sometimes a preheater or fluidizing features to maintain consistent flow. An electrostatic spray gun uses an electrical charge to attract powder particles to the surface being coated, producing a uniform, adherent finish.

Key factors that influence the match between hopper and gun include powder flow characteristics, powder conductivity, hopper agitation, feed rate, nozzle design, and the operating voltage of the gun. A mismatch can lead to clogging, inconsistent powder flow, poor transfer efficiency, and defect-prone finishes.

Assessing your material: powder properties that affect matching

Before selecting hardware, analyze the powder you will apply. The main material properties to consider are:

- Flowability: How easily the powder flows through the feed system. Poor flow can cause streaks or irregular film thickness.

- Particle size distribution: A narrow distribution tends to feed more predictably; very fine powders may require specialized agitation or fluidization.

- Flow aid requirements: Some powders require additives or preconditioning to improve flow, such as air fluidization or mechanical vibration.

- Conductivity: Conductive powders respond well to electrostatic charging; non-conductive powders may require corona-assisted or tribo charging and proper grounding.

- Moisture content: Moisture can cause clumping and inconsistent flow; maintain low humidity and dry powder storage.

Choosing the right hopper: capacity, material, and features

When selecting a powder hopper, consider these aspects:

- Capacity and size: Choose a hopper that matches your production pace and the spray booth cycle time. Larger hoppers reduce refill frequency but may increase dead weight and heat buildup.

- Material: Stainless steel or high-grade aluminum are common for chemical resistance and durability. Some lower-cost options may use painted steel; verify compatibility with your powder and cleaning regime.

- Fluidization and agitation: Look for built-in air fluidization, vibration, or a combination to keep powder in a fluidized state for consistent flow.

- Sight glass or level indicator: Ensures you can monitor powder level without interrupting production.

- Quick-change features: Removable liners and accessible feeding tubes speed up color changes and cleaning.

- Seals and gasket quality: Ensure airtight seals to prevent moisture ingress and powder backflow.

- Cleanability: Smooth interior surfaces, removable agitators, and accessible outlets simplify cleaning to prevent cross-contamination.

Matching hopper type to spray gun technology

Electrostatic spray guns come in several generations and configurations, including corona (charged) guns, tribostatic (inductive) systems, and newer high-transfer-efficiency designs. The hopper-gun match depends on how powder is fed and charged.

- Corona-powered systems: These often pair well with fluidized, well-fluidized hoppers that provide steady, consistent flow. Ensure the hopper's agitation maintains a uniform feed to prevent powder spikes.

- Triboelectric or inductive systems: These may benefit from gentle, controlled feed with reduced shear forces. A hopper with smooth, non-shedding materials and controlled vibration helps maintain consistent particle charging.

- Low-pressure versus high-voltage setups: High-voltage guns may require powders with stable flow characteristics to avoid electrical arcing or inconsistent charging. A well-mixed, steady feed from the hopper helps stabilize transfer efficiency.

Setup steps: installing and tuning the hopper with your gun

- Step 1: Place the hopper in an accessible area within the paint booth, ensuring there is adequate clearance for refilling and cleaning.

- Step 2: Confirm that the hopper is properly grounded or that any anti-static measures are in place if the system requires them.

- Step 3: Install the feed tube and connect the agitator to the hopper's drive mechanism. Check for secure fittings with no wobble.

- Step 4: Set the agitation speed to achieve a fluidized powder bed without introducing excessive airflow that could create powder leakage or dusting around the booth.

- Step 5: Verify the fluidization air supply (if present). Adjust to achieve a light, even bubbling of the powder surface without blowing powder out of the hopper.

- Step 6: Attach the powder return lines or recirculation loops if your system is designed for continuous circulation. Ensure there are no kinks and that the powder can re-enter the hopper smoothly.

- Step 7: Connect the hopper outlet to the spray gun's feed line. Ensure there is no restriction, and that the connection is airtight.

- Step 8: Calibrate feed rate settings on the spray gun. Start at a conservative baseline and gradually increase while watching for consistency in coating thickness and transmission efficiency.

- Step 9: Grounding and shielding checks. Confirm that the workpiece, spray gun, and booth are properly grounded to prevent arcing and ensure stable deposition.

- Step 10: Run a test panel. Observe powder deposition, film build, and adhesion. Adjust hopper agitation and feed rate to reduce edge build-ups or sags.

Troubleshooting common issues

- Inconsistent powder flow: Check for moisture condensation, clogged outlets, worn seals, or improper fluidization pressure. Clean the hopper regularly and inspect the feed level indicators.

- Powder streaking or non-uniform film: Verify fluidization is even and that the feed rate matches the gun's spray pattern. Inspect nozzle alignment and grounding.

- Excessive overspray and dusting: Reduce agitation intensity, wire brush any rough interior surfaces, and ensure seal integrity. Consider a return-loop redesign to minimize dust escape.

- Color changes requiring long purge times: Use a color-change kit with clean-out procedures. Pre-clean the hopper interior and remove residual powder from the feed line.

- Arcing or poor charging: Check the powder's conductivity and humidity levels. Ensure connectors, grounding wires, and the spray gun's electrode system are in good condition.

Maintenance and cleaning practices

- Regular cleaning schedule: Implement daily, weekly, and monthly cleaning routines to minimize cross-contamination and maintain consistent flow.

- Interior inspections: Periodically inspect interior surfaces for wear, pitting, or corrosion. Replace worn agitators or liners as needed.

- Seals and fittings: Inspect all seals for cracks, and replace gaskets that show signs of wear or moisture ingress.

- Calibration checks: Periodically recheck feed rate calibration against film thickness measurements to ensure accuracy.

- Storage and handling: Store powders in dry, climate-controlled spaces to prevent clumping and degradation. Use sealed containers and minimize exposure to ambient humidity.

How to optimize transfer efficiency and finish quality

- Powder flow and charging balance: Ensure a steady feed that matches the gun's charging rate. Sudden changes in flow disrupt charging and create film thickness variation.

- Booth pressure and airflow: Maintain proper booth ventilation and positive pressure to reduce backflow of overspray and keep powder in the intended path.

- Panel geometry and distance: Adjust gun-to-substrate distance to optimize deposition uniformity. Use masking or fixturing to prevent edge build-up on complex shapes.

- Pretreatment compatibility: Ensure surface preparation is appropriate for the powder film. Inadequate surface prep can cause adhesion issues that are misattributed to the hopper or gun.

- Process monitoring: Use thickness gauges or in-line inspection tools to monitor coating thickness and adjust the system in real time.

Safety considerations

- Electrical safety: High-voltage components require proper shielding, grounding, and adherence to electrical safety standards.

- Fire and explosion risk: Powder handling and electrostatic systems can create ignition hazards. Keep auto-ignition sources away, maintain clean and well-ventilated spaces, and follow local regulations for explosive atmosphere avoidance.

- Personal protective equipment: Use appropriate PPE, including respirators, safety glasses, and gloves, when handling powders and cleaning equipment.

- Chemical compatibility: Ensure all parts in contact with powders are compatible with their chemical properties to prevent degradation and contamination.

Cost considerations and return on investment

- Initial capex: A high-quality hopper with fluidization, agitation, and easy-clean features may have a higher upfront cost but can reduce downtime and waste.

- Operating costs: Improved transfer efficiency lowers powder consumption and energy use. Reduced rework and faster cycle times contribute to a favorable total cost of ownership.

- Maintenance: Durable materials and modular components simplify repairs and parts replacement, lowering long-term maintenance costs.

- Downtime impact: A reliable hopper-gun pairing minimizes interruptions, improving overall production throughput.

Best practices for color changes and maintenance cycles

- Color changes: Plan a color-change procedure that minimizes waste and reduces purge times. Use a dedicated purge station or clear-out sequence to prevent cross-contamination.

- Regular maintenance: Schedule routine checks for seals, agitators, fluidization tips, and feed lines. Replace worn parts promptly to avoid unplanned downtime.

- Documentation: Maintain records of maintenance cycles, calibration results, and any adjustments made during production runs. This helps with traceability and quality control.

Proven setup patterns for different production scales

- Small-batch shops: Prioritize quick-change components, easy cleaning, and compact hoppers. Emphasize modularity so you can adapt to varied product lines.

- Mid-sized plants: Balance hopper capacity with downtime-reducing features like efficient cleaning ports and accessible fluidization controls. Implement standardized color-change procedures.

- Large-scale operations: Invest in automated material handling, centralized purge and cleaning stations, and remote monitoring of hopper status, feed rates, and booth conditions.

FAQs

1) How do I know if my hopper is fluidized correctly for an electrostatic gun?

- You should see a consistent, gentle bubbling of the powder surface with minimal agglomeration. If the surface sits flat or powder clumps, adjust the air flow or agitator speed.

2) Can I use any powder with any electrostatic spray gun?

- Not all powders are compatible with all guns. Check the powder's conductivity, flow characteristics, and recommended equipment for compatibility with your specific spray gun model.

3) What is the impact of humidity on hopper performance?

- High humidity can cause powder clumping and inconsistent flow. Keep the storage area dry and ensure proper humidity control in the booth and hopper housing.

4) How often should I clean the hopper?

- Clean the hopper regularly based on usage frequency and color-change cycles. Conduct thorough cleanouts during major color changes or maintenance shutdowns.

5) What maintenance steps are essential to maximize transfer efficiency?

- Regular inspection of seals, agitation systems, fluidization air passages, and the feed line, plus timely replacement of worn parts and calibration checks.

Conclusion

Matching the powder hopper to your electrostatic spray gun is a foundational step in achieving consistent coatings, high transfer efficiency, and reduced waste. By understanding powder properties, selecting the right hopper features, and following careful setup, maintenance, and optimization practices, you can create a robust, repeatable coating process that scales with your production needs.

FQAS

- How does powder conductivity influence hopper selection for electrostatic spraying?

- What characteristics make a powder hopper easy to clean and color-change-friendly?

- Which maintenance practices most reliably extend hopper life in a busy production environment?

- How can you optimize booth airflow to complement a matched hopper and gun setup?

- What are the key indicators of a well-matched hopper-gun system during a production run?

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.