Content Menu

● The Crucial Role of Sieving in Powder Coating

>> Achieving Optimal Film Smoothness

>> Understanding Particle Size and Its Impact

● Types of Sieving Technologies

>> Vibratory Sieves

>>> High-Energy Vibratory Sieves

>> Other Sieving Considerations

>>> Molecular Sieves in Coatings

● Factors to Consider When Choosing a Sieve

>> Powder Characteristics

>> Desired Output and Throughput

>> Sieve Mesh Size and Material

>> Maintenance and Downtime

>> Budget and Cost-Effectiveness

>> Supplier Expertise and Support

● Advanced Sieving Strategies for Optimal Coating Quality

>> Integration with Grinding and Milling Processes

>> Quality Control and Monitoring

>> Addressing Specific Coating Challenges

>> The Role of Formulation in Sieve Selection

● Conclusion

● Related Questions and Answers

>> Q1: What is the recommended starting sieve size for achieving high-gloss and smooth powder coatings?

>> Q2: How does particle size distribution affect the smoothness of powder coatings?

>> Q3: What issues can arise from oversized particles in powder coating?

>> Q4: What are the advantages of using a high-energy vibratory sieve like the Hi-Sifter for powder coatings?

>> Q5: In what scenarios might a 100-micron sieve be necessary, and what are its potential consequences?

>> Q6: How do molecular sieves differ from traditional powder sieves in coating applications?

Powder coating is a widely adopted finishing process in various industries, from automotive to household appliances, recognized for its durability, eco-friendliness, and aesthetic appeal. The success of a high-quality powder coating finish hinges significantly on the uniformity and purity of the powder applied [3]. Even minor inconsistencies in particle size distribution can lead to imperfections, affecting both the visual appeal and the performance of the coated surface [3]. Therefore, precise screening and sieving of powder coatings are crucial to ensure that only particles of the desired size reach the application phase, ultimately yielding smoother finishes, enhanced durability, and improved aesthetic quality [3].

The Crucial Role of Sieving in Powder Coating

Sieving is an indispensable step in the powder coating process, serving as a critical quality control measure. It ensures that the powder meets specific size requirements, which is vital for achieving consistent and high-quality finishes [3]. Oversized particles can obstruct spraying equipment, while fine particles that deviate from the target size can compromise the uniformity of coverage [3]. By accurately sieving powder coatings, manufacturers can significantly enhance product quality and minimize waste [3]. The choice of the right mesh size for the sieving screen is paramount, often requiring a balance between fine sieving for higher quality and efficient throughput [9].

Achieving Optimal Film Smoothness

For high-gloss and smooth powder coatings, a narrow particle size distribution is essential [1]. The "scalp," or the top end of particle sizes, plays a critical role in achieving the desired smoothness [1]. Initial recommendations for sieve size often suggest starting with a 125-micron screen, followed by an evaluation of particle size distribution and film smoothness [1]. If the desired smoothness is not achieved, moving to a 100-micron screen may be necessary [1]. While a 100-micron screen typically yields the desired smoothness, it may result in a larger quantity of "overs" (particles greater than 100 microns) [1]. This coarser fraction can be reintroduced into the milling process to optimize yield [1]. If, even after these adjustments, the desired smoothness remains elusive, it may indicate a need to reduce the viscosity of the resin system or slow down the cure rate of the resin/crosslinker [1].

Understanding Particle Size and Its Impact

The particle size of the powder is a fundamental characteristic that directly influences the coating's performance and appearance.

* Larger particles can lead to an uneven surface, a rough texture, and potential clogging of application equipment [3]. They might also fail to properly melt and flow during the curing process, resulting in defects [3].

* Smaller particles (fines), while contributing to a smoother finish when within the desired range, can pose their own challenges [1]. An excessive accumulation of fine particles, especially from reclaimed powder, can lead to issues like declining powder coating coverage over time [1]. It is important to manage the grinding process to minimize both fines (less than 10 microns) and coarse fractions (greater than 100 microns) [1].

Good milling conditions are crucial for minimizing waste and ensuring a narrow particle size distribution [1]. Optimizing rotor speed and classifier wheel settings helps achieve this balance [1].

Types of Sieving Technologies

Various sieving technologies are available, each with its own advantages and suitable applications. Choosing the right one depends on factors like the volume of powder to be processed, the required level of precision, and the characteristics of the powder itself.

Vibratory Sieves

Vibratory sieves are a common choice in powder coating applications. They use vibration to separate particles by size. Advanced vibratory sieving technologies are engineered to handle challenging powder coatings, screening particles to precise sizes while maintaining consistent quality [3].

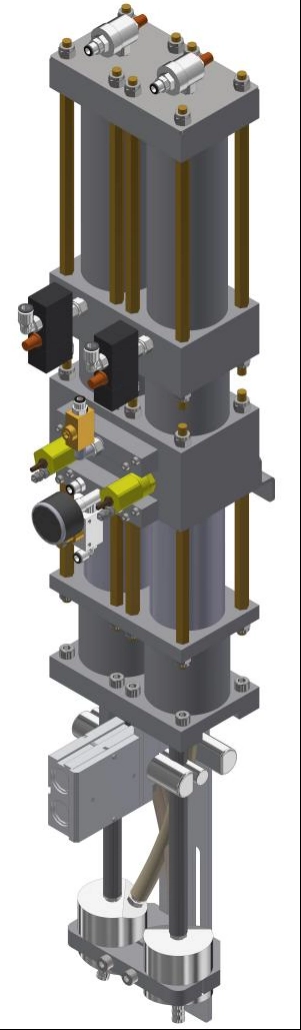

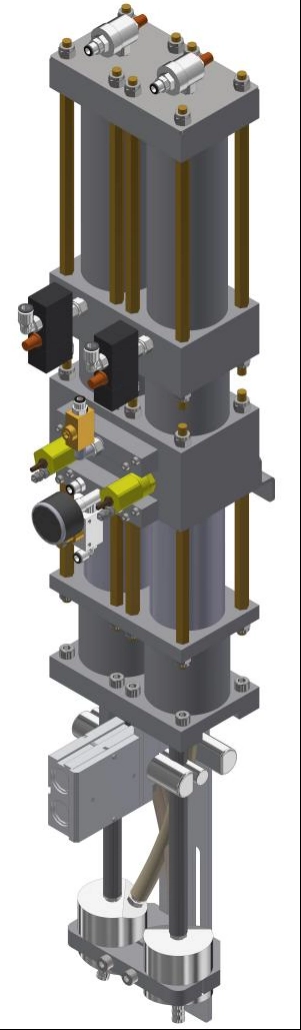

High-Energy Vibratory Sieves

The Hi-Sifter technology, for instance, is a high-energy vibratory sieve designed to address common challenges in powder coating sieving [3]. It excels at maintaining a free-flowing powder, preventing agglomeration, and achieving particle sizes as fine as 5 microns without clogging or slowing down [3].

Key advantages of high-energy vibratory sieves like the Hi-Sifter include:

* Mesh Blinding Prevention: A significant issue with fine powders is mesh blinding, where particles clog the sieve mesh, reducing throughput [3]. High-energy approaches counteract this, ensuring a consistent material flow [3].

* Precise Particle Size Control: These sieves can screen powders to exact specifications, guaranteeing that only desired particle sizes proceed, which is vital for consistent finishes [3].

* High Throughput: Designed to handle large volumes accurately, they enable faster processing times and greater efficiency for bulk powder coating operations [3].

* Reduced Downtime: Their robust construction and efficient operation lead to less maintenance, maximizing productivity for manufacturers [3].

Other Sieving Considerations

While vibratory sieves are prevalent, other systems like molecular sieves also play a role, particularly in specialized coating formulations.

Molecular Sieves in Coatings

Molecular sieves are materials with uniform pores that selectively adsorb molecules based on their size and shape [5]. They are widely used in coatings to control moisture, remove impurities, and enhance formulation stability [5]. Molecular sieves are typically composed of zeolites, carbon, silica gel, or synthetic polymers [5].

Molecular sieves are available in both powder and paste forms, with the paste form offering several benefits in high-performance coatings [5]:

* Enhanced Dispersion: Molecular sieve paste disperses more uniformly within the coating matrix compared to powder, ensuring even distribution of sieve particles for effective moisture and impurity control [5]. This uniform dispersion is crucial for maintaining performance and durability [5].

* Anti-Settling Characteristics: Unlike powder forms that tend to settle, molecular sieve paste has anti-settling properties, leading to more consistent formulations and application [5]. The paste form reincorporates more easily, ensuring a homogeneous mixture that performs consistently [5].

* Ease of Incorporation: Incorporating molecular sieve paste is simpler and less messy than using powder, reducing dust generation and minimizing potential health hazards associated with inhaling fine particles [5]. This makes the manufacturing process safer and more efficient [5].

* Improved Stability: Molecular sieve paste enhances coating formulation stability, helping to maintain viscosity and flow properties and preventing issues like clumping or agglomeration common with powders [5]. This stability is vital for achieving a smooth, even application and optimal coating performance [5].

* Consistent Performance: The benefits listed above collectively contribute to more consistent performance of the coating over time [5].

While molecular sieves serve a different purpose than standard powder sieves—primarily impurity control rather than general particle size distribution for application—their form can influence overall coating quality.

Factors to Consider When Choosing a Sieve

Selecting the appropriate powder sieve involves evaluating several key factors to ensure optimal performance and coating quality.

Powder Characteristics

The nature of the powder itself is a primary consideration. Factors such as particle shape, density, flowability, and electrostatic properties can influence how effectively it can be sieved.

* Particle Size Distribution (PSD): Understanding the existing PSD of your powder is crucial for selecting the appropriate mesh size [1].

* Material Sensitivity: Some powders are sensitive to heat or excessive agitation, which might influence the type of sieving technology chosen.

Desired Output and Throughput

The volume of powder to be processed and the required speed of processing are critical in selecting a sieve.

* Batch vs. Continuous Processing: Determine whether you need to sieve batches of powder or have a continuous flow operation.

* Throughput Requirements: High-throughput systems, like certain vibratory sieves, are designed to handle large volumes without compromising accuracy, making them suitable for bulk processing [3].

Sieve Mesh Size and Material

The mesh size directly determines the fineness of the sieving process and, consequently, the smoothness of the final coating [1].

* Starting Point: A 125-micron screen is a common starting point for powder coating, with adjustments to 100-micron if finer results are needed [1].

* Compromise: A finer mesh generally grants higher-quality sieving, but it can also impact throughput and may lead to more "overs" [9][1].

* Mesh Material: The material of the sieve mesh should be durable and resistant to abrasion from the powder. Stainless steel is a common choice due to its robustness and resistance to corrosion.

Maintenance and Downtime

The design of the sieve can impact the ease of cleaning and maintenance, which in turn affects operational efficiency.

* Ease of Cleaning: Sieves that are easy to disassemble and clean reduce downtime.

* Durability: A robust build and efficient operation minimize maintenance needs, maximizing productivity [3].

Budget and Cost-Effectiveness

The initial investment and ongoing operational costs are important considerations.

* Initial Cost: Evaluate the upfront cost of the sieving equipment.

* Operational Costs: Consider power consumption, labor requirements, and maintenance expenses.

* Return on Investment (ROI): A more efficient sieve might have a higher initial cost but could offer a better ROI through improved product quality, reduced waste, and increased throughput.

Supplier Expertise and Support

Partnering with suppliers who have extensive experience in sieving technology for powder coatings can provide tailored solutions and support [3].

* Testing Facilities: Some suppliers offer toll processing facilities where companies can test their powders with advanced sieving equipment, allowing them to witness the benefits firsthand [3].

* Specialized Knowledge: Expertise beyond just sieving, covering specific needs and challenges of various powder coatings, can be invaluable [3].

Advanced Sieving Strategies for Optimal Coating Quality

Beyond simply choosing the right sieve, implementing advanced strategies can further enhance the efficiency and quality of powder coating operations.

Integration with Grinding and Milling Processes

Optimizing the grinding process is fundamental to managing particle size distribution before sieving [1].

* Pre-Sieve Optimization: Fine-tuning rotor speed and classifier wheel settings in the mill can minimize both fine and coarse fractions, reducing the burden on the sieving equipment and improving overall yield [1].

* Reintroducing Overs: Coarse fractions (overs) can be reintroduced into the mill, promoting a more circular and efficient material flow [1].

Quality Control and Monitoring

Continuous monitoring of particle size distribution and film smoothness is essential to ensure consistent quality [1].

* Regular Checks: Implement regular checks on the sieved powder's particle size distribution and the final film smoothness [1].

* Feedback Loop: Use data from these checks to adjust sieve parameters or milling conditions as needed, creating a continuous improvement cycle [1].

Addressing Specific Coating Challenges

Different coating applications may have unique challenges that require specific sieving approaches.

* High Gloss Coatings: These coatings demand a particularly narrow particle size distribution for maximum smoothness, necessitating very fine sieving [1].

* Textured Coatings: While less stringent on smoothness, uniform particle size is still important for consistent texture.

* Specialty Coatings: Coatings with unique additives or compositions may require customized sieving solutions.

The Role of Formulation in Sieve Selection

The chemical composition and viscosity of the powder coating formulation can impact the sieving process and the final outcome.

* Resin Viscosity and Cure Rate: If desired smoothness is not achieved despite optimal sieving, reducing resin viscosity or slowing the cure rate of the resin/crosslinker can be explored [1]. These aspects of the formulation directly influence how the powder melts and flows during curing, impacting the final film quality.

* Additives: The inclusion of certain additives, such as molecular sieve paste for moisture control, can influence the overall flow properties of the powder and thus the sieving efficiency [5]. The paste form of molecular sieves is preferred for its better dispersion and anti-settling characteristics compared to powder [5].

Conclusion

Choosing the right powder sieve for high-efficiency coating is a multifaceted decision that directly impacts the quality, durability, and aesthetic appeal of the final product. It involves a thorough understanding of particle size dynamics, the capabilities of various sieving technologies, and the interplay between powder characteristics and process requirements. By carefully considering factors such as desired smoothness, throughput, maintenance, and budget, and by integrating advanced strategies like pre-sieve optimization and continuous quality monitoring, manufacturers can ensure optimal performance. The goal is to achieve precise particle size control, prevent issues like mesh blinding, and maximize efficiency, ultimately leading to superior coating results and reduced waste. The selection of a sieve is not merely a technical choice but a strategic investment in achieving unparalleled quality in powder coating applications.

Related Questions and Answers

Q1: What is the recommended starting sieve size for achieving high-gloss and smooth powder coatings?

A1: A recommended starting point for sieve size is a 125-micron screen. If the desired smoothness is not achieved, a 100-micron screen can then be used.

Q2: How does particle size distribution affect the smoothness of powder coatings?

A2: For high-gloss and smooth powder coatings, a narrow particle size distribution is critical. The upper limit of particle sizes, referred to as the "scalp," is particularly important for ensuring the desired smoothness.

Q3: What issues can arise from oversized particles in powder coating?

A3: Oversized particles can cause clogging in spraying equipment and lead to imperfections on the coated surface, affecting both visual appeal and performance.

Q4: What are the advantages of using a high-energy vibratory sieve like the Hi-Sifter for powder coatings?

A4: High-energy vibratory sieves like the Hi-Sifter offer several advantages, including preventing mesh blinding, providing precise particle size control, enabling high throughput, and reducing downtime due to their durable build and efficient operation.

Q5: In what scenarios might a 100-micron sieve be necessary, and what are its potential consequences?

A5: A 100-micron sieve may be necessary if a 125-micron screen does not produce the desired smoothness. While it should yield better smoothness, it might result in a larger quantity of "overs" (particles greater than 100 microns) that can be reintroduced to the mill to manage yield.

Q6: How do molecular sieves differ from traditional powder sieves in coating applications?

A6: Molecular sieves are primarily used in coatings to control moisture and remove impurities by selectively adsorbing molecules based on size and shape. Traditional powder sieves, conversely, are used for separating and classifying powder particles by size to ensure uniformity for application.

[1] https://www.pfonline.com/articles/proper-sieve-size-for-powder-coatings-smooth-results

[2] https://www.sigmaaldrich.com/SG/zh/search/layer?focus=products&page=1&perpage=30&sort=relevance&term=layer&type=product_name

[3] https://elcanindustries.com/blog_posts/powder-coating-sieves-what-are-the-pros-and-cons-heres-what-you-need-to-know/

[4] https://blog.csdn.net/2401_84911273/article/details/138954445

[5] https://pflaumer.com/the-benefits-and-importance-of-using-molecular-sieve-paste-in-high-performance-coatings/

[6] https://patents.google.com/patent/CN113195163A/zh

[7] https://www.russellfinex.com/en/news-and-events/choosing-right-vibratory-sieve-screener-guide/

[8] https://patents.google.com/patent/CN101805152B/zh

[9] https://www.gemapowdercoating.com/fileadmin/documents/Learn_More/Sieving_solutions_169.pdf

[10] https://patents.google.com/patent/WO2013078757A1/zh

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.