Content Menu

● Introduction

● Understanding the Fundamentals

>> What Is an Integrated Control System?

>> What Is a Hybrid System?

● Cost-Effectiveness: The Core Comparison

>> Upfront Investment

>> Operational Costs

>> Maintenance and Upkeep

>> Scalability and Flexibility

>> Long-Term Value and Sustainability

● Case Studies and Real-World Applications

>> Energy Sector

>> Industrial Automation

● Advantages and Disadvantages

>> Integrated Control Systems

>> Hybrid Systems

● Decision-Making Factors

● Security Considerations

● The Future Outlook

● Frequently Asked Questions

Introduction

In the rapidly evolving landscape of modern technology and energy management, the debate between integrated control systems and hybrid systems has become increasingly relevant. As organizations and industries strive for greater efficiency, cost savings, and sustainability, understanding the strengths and trade-offs of these two approaches is critical. This article provides a comprehensive analysis of integrated control systems and hybrid systems, focusing on their cost-effectiveness, operational performance, scalability, and long-term value.

Understanding the Fundamentals

What Is an Integrated Control System?

An integrated control system is a unified platform that manages and automates various processes or subsystems within an organization or facility. Typically, these systems are designed to streamline operations, reduce redundancies, and provide centralized monitoring and control. Integrated control systems are often favored for their simplicity, ease of management, and reduced risk of incompatibility between subsystems.

What Is a Hybrid System?

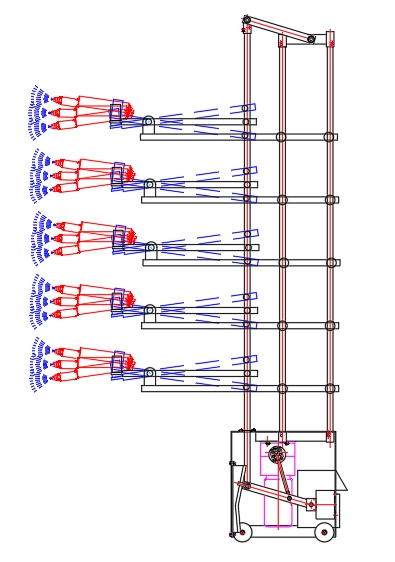

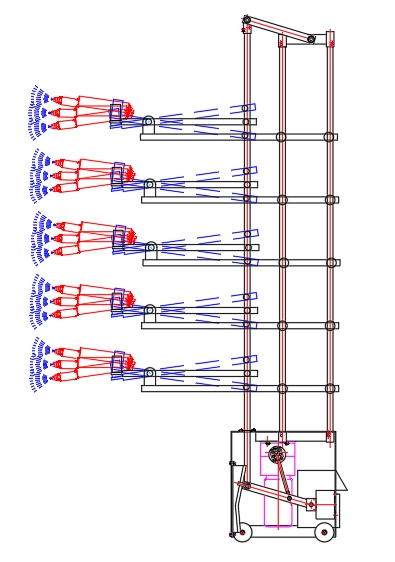

A hybrid system, by contrast, combines multiple technologies, sources, or methodologies to achieve a more flexible and adaptable solution. For example, in the context of energy management, a hybrid system might integrate renewable sources like solar and wind with traditional power generation and energy storage. The goal is to leverage the strengths of each component to enhance reliability, performance, and sustainability.

Cost-Effectiveness: The Core Comparison

Upfront Investment

Integrated Control Systems:

- Generally involve lower upfront costs due to their single-platform nature.

- Simplified installation and commissioning processes reduce the need for specialized labor and minimize initial capital expenditure.

- Standardized components and interfaces further decrease procurement and integration expenses.

Hybrid Systems:

- Require higher initial investment due to the complexity of integrating multiple technologies.

- Installation and design demand specialized expertise, increasing labor and engineering costs.

- Customization and compatibility checks add to the upfront financial burden.

Operational Costs

Integrated Control Systems:

- Centralized management leads to lower ongoing operational costs.

- Maintenance is streamlined, as there is typically a single vendor or service provider responsible for support.

- Energy consumption can be optimized, but flexibility is limited compared to hybrid configurations.

Hybrid Systems:

- Operational costs can be lower in the long term, especially when renewable energy sources are included, reducing reliance on expensive traditional fuels.

- However, maintenance is more complex and costly due to the need to service multiple components and technologies.

- Advanced monitoring and management tools are required to ensure seamless operation, adding to ongoing expenses.

Maintenance and Upkeep

Integrated Control Systems:

- Easier and less expensive to maintain, as all components are designed to work together.

- Fewer points of failure and standardized troubleshooting procedures.

- Upgrades and expansions are straightforward but may be limited by the system's architecture.

Hybrid Systems:

- Maintenance is more challenging, as each subsystem may require different expertise and spare parts.

- Integration points can become sources of failure or inefficiency.

- Upgrades may necessitate significant re-engineering to maintain compatibility and performance.

Scalability and Flexibility

Integrated Control Systems:

- Offer limited scalability, as expanding the system often requires significant redesign or replacement of existing components.

- Flexibility is constrained by the system's architecture and vendor support.

Hybrid Systems:

- Highly scalable and adaptable, allowing organizations to add or modify components as needs evolve.

- Can integrate new technologies more easily, supporting innovation and future-proofing investments.

Long-Term Value and Sustainability

Integrated Control Systems:

- Provide stable, predictable performance with minimal surprises.

- Best suited for environments where requirements are unlikely to change significantly over time.

- May become obsolete faster if technological advancements outpace the system's capabilities.

Hybrid Systems:

- Deliver greater long-term value by accommodating emerging technologies and changing operational demands.

- Support sustainability goals by integrating renewable energy and reducing environmental impact.

- Offer resilience against market and regulatory changes, such as shifts in energy prices or emissions standards.

Case Studies and Real-World Applications

Energy Sector

Hybrid energy systems, such as those combining solar, wind, and traditional power sources, have demonstrated significant cost savings and improved reliability in various global contexts. For example, optimized hybrid renewable energy systems have reduced the cost of energy in India and Turkey, while also enhancing sustainability and resilience. These systems often achieve payback periods of less than a decade, making them attractive for both public and private sector investments.

Integrated control systems, on the other hand, are preferred in environments where operational simplicity and reliability are paramount, such as in manufacturing or critical infrastructure. Here, the ability to monitor and control all processes from a single interface reduces the risk of errors and downtime.

Industrial Automation

In manufacturing, integrated control systems streamline production lines and ensure consistent quality. However, as product complexity and customization demands increase, hybrid systems that combine traditional automation with advanced robotics and AI are becoming more prevalent. These hybrid approaches enable manufacturers to respond quickly to market changes and customer preferences.

Advantages and Disadvantages

Integrated Control Systems

Advantages:

- Lower upfront and operational costs

- Simplified maintenance and management

- High reliability and stability

- Easier to secure and protect from cyber threats

Disadvantages:

- Limited flexibility and scalability

- Potential for obsolescence

- Less adaptable to new technologies or changing requirements

Hybrid Systems

Advantages:

- Enhanced performance and adaptability

- Greater scalability and future-proofing

- Support for sustainability and renewable integration

- Improved resilience and reliability in dynamic environments

Disadvantages:

- Higher upfront and maintenance costs

- Increased complexity in design and operation

- Greater security challenges due to multiple integration points

Decision-Making Factors

When deciding between an integrated control system and a hybrid system, organizations should consider the following factors:

- Nature of Operations: Stable, predictable environments favor integrated systems, while dynamic or rapidly evolving operations benefit from hybrid solutions.

- Budget Constraints: Limited capital may necessitate an integrated system, but long-term savings from a hybrid approach could justify the higher initial investment.

- Sustainability Goals: Organizations aiming to reduce their environmental footprint will find hybrid systems more aligned with their objectives.

- Technical Expertise: Availability of skilled personnel to manage complex hybrid systems is critical for success.

- Future Growth: Anticipated expansion or technological upgrades support the case for hybrid systems.

Security Considerations

Integrated control systems are generally more secure due to their standardized architecture and fewer integration points. Hybrid systems, while offering superior performance, introduce additional vulnerabilities that must be managed through robust cybersecurity measures and regular audits.

The Future Outlook

As technology continues to advance, the distinction between integrated and hybrid systems may blur. Integrated platforms are increasingly incorporating modular, hybrid-like features, while hybrid systems are becoming easier to manage through sophisticated control software. Ultimately, the choice will depend on the specific needs, goals, and resources of each organization.

Frequently Asked Questions

1. What are the primary cost drivers for integrated control systems and hybrid systems?

Integrated control systems are primarily driven by hardware, software, and installation costs, with ongoing expenses related to maintenance and updates. Hybrid systems incur higher initial costs due to complexity and integration but can achieve long-term savings through operational efficiencies and renewable energy integration.

2. How do hybrid systems contribute to sustainability goals?

Hybrid systems enable the integration of renewable energy sources, reducing reliance on fossil fuels and lowering greenhouse gas emissions. This supports organizational and regulatory sustainability targets.

3. Are hybrid systems always more cost-effective in the long run?

Not necessarily. While hybrid systems offer potential for long-term savings, their cost-effectiveness depends on factors such as system design, energy prices, maintenance requirements, and the availability of skilled personnel.

4. What industries benefit most from integrated control systems?

Industries with stable, well-defined processes—such as manufacturing, utilities, and critical infrastructure—benefit most from integrated control systems due to their simplicity and reliability.

5. What are the main challenges in maintaining hybrid systems?

The main challenges include the need for specialized expertise, increased maintenance complexity, and ensuring compatibility between diverse components. Security is also a greater concern due to multiple integration points.

[1] https://www.sciencedirect.com/science/article/pii/S259012302300748X

[2] https://www.sciencedirect.com/science/article/abs/pii/S0960148122015233

[3] https://buildops.com/resources/hybrid-system/

[4] https://www.esig.energy/wp-content/uploads/2022/03/ESIG-Hybrid-Resources-report-2022.pdf

[5] https://diversegy.com/hybrid-energy-solutions/

[6] https://www.ee.cityu.edu.hk/~gchen/pdf/Writing.pdf

[7] https://www.nrel.gov/news/detail/features/2021/are-hybrid-systems-truly-the-future-of-the-grid

[8] https://blog.csdn.net/weixin_34401008/article/details/117943281

[9] https://www.nature.com/articles/s41598-025-87985-7

[10] https://www.cnblogs.com/luohenyueji/p/16990846.html

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.