Content Menu

● Understanding Reciprocators in Coating Applications

>> What is a Reciprocator?

>> Functions and Importance

● Entry-Level Reciprocators: Features and Benefits

>> Overview of Entry-Level Models

>> Common Features

>> Advantages of Entry-Level Reciprocators

>> Limitations of Entry-Level Reciprocators

● Advanced Reciprocators: Features and Benefits

>> Overview of Advanced Models

>> Key Features

>> Advantages of Advanced Reciprocators

>> Potential Drawbacks

● Comparing Entry-Level and Advanced Reciprocators: Important Criteria

>> Performance and Precision

>> Application Complexity

>> Production Volume

>> Budget Considerations

>> Maintenance and Support

● Use Cases for Entry-Level Reciprocators

>> Small Workshops and Startups

>> Limited Product Variety

>> Pilot or Prototype Production

● Use Cases for Advanced Reciprocators

>> Automotive and Aerospace Industries

>> Electronics Manufacturing

>> Large-Scale Industrial Production

● Tips for Selecting the Right Reciprocator for Your Line

>> Assess Your Production Needs

>> Evaluate Budget and ROI

>> Consider Future Growth

>> Ask About Integration

>> Check Service and Support

● Frequently Asked Questions (FAQ)

● Conclusion

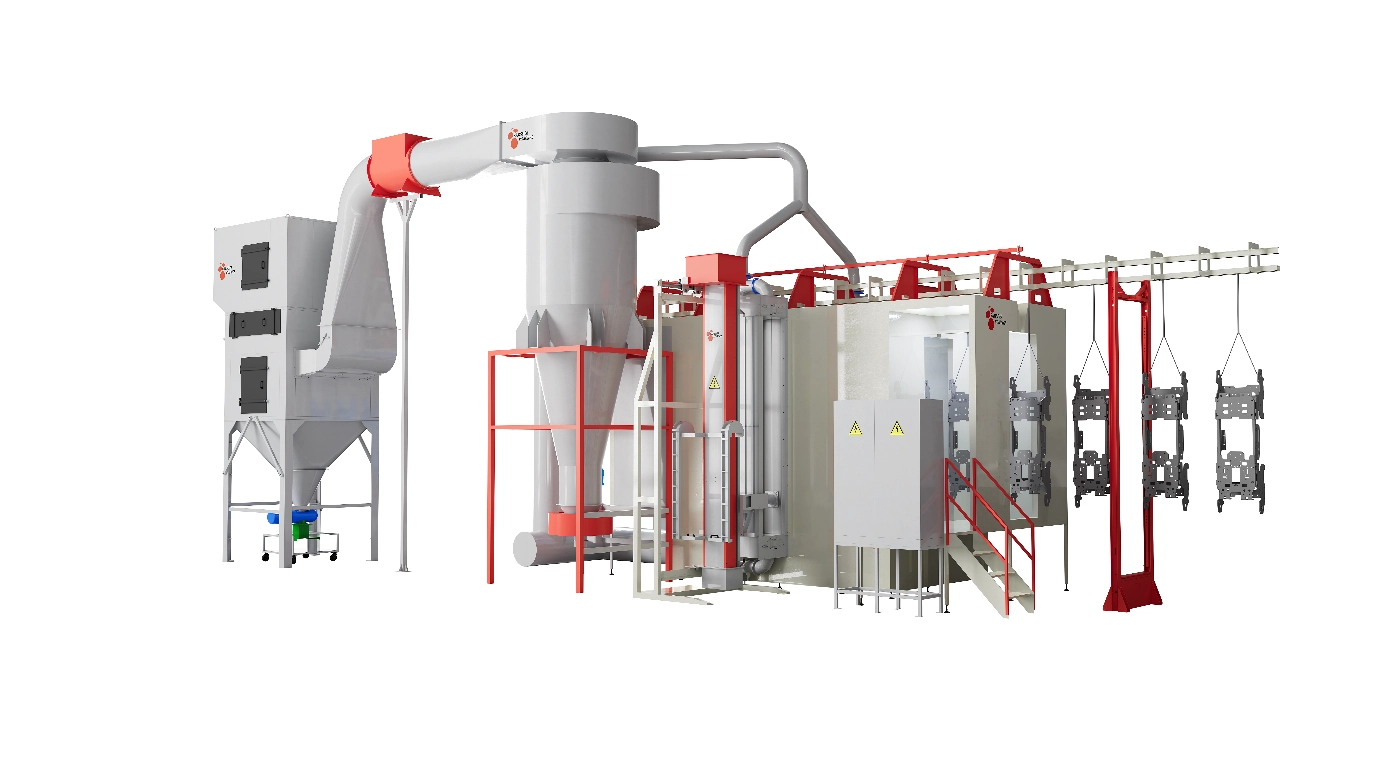

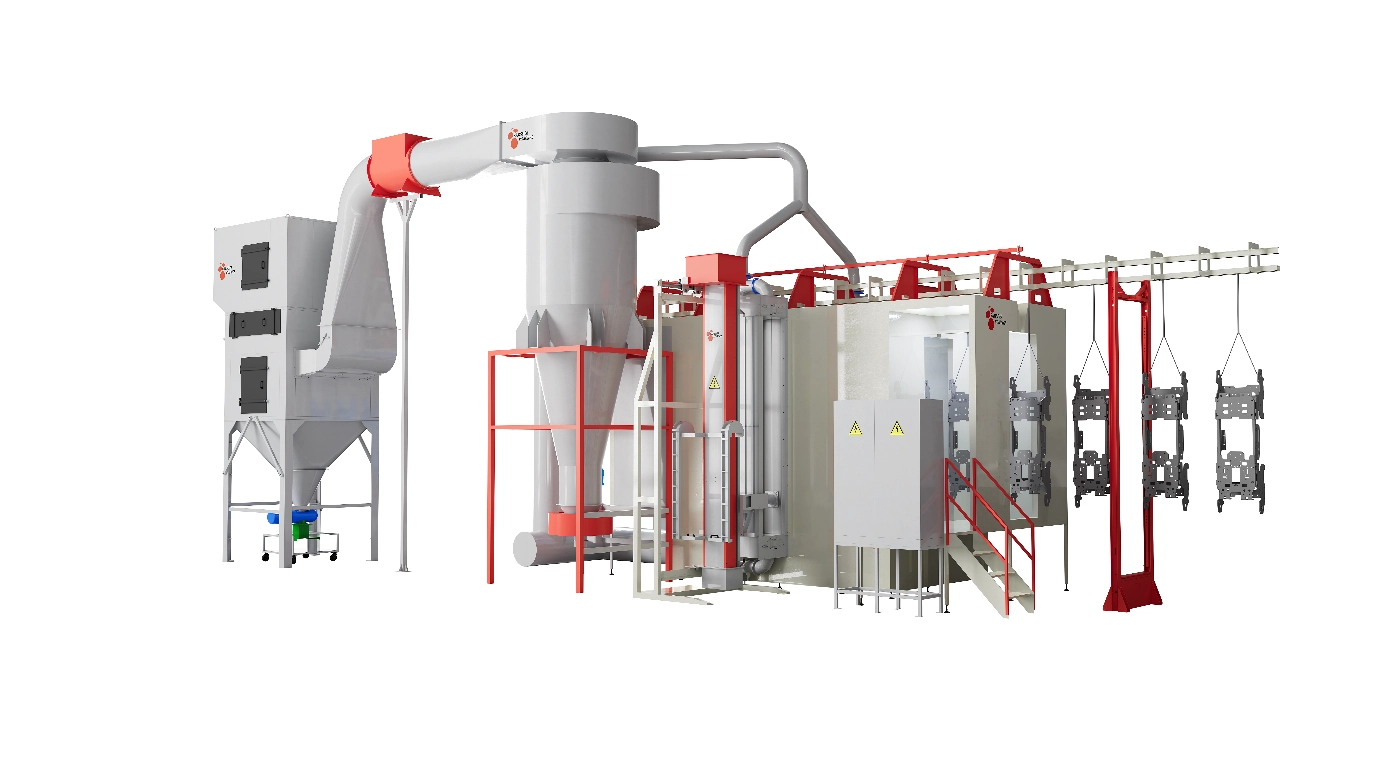

In the world of industrial coating applications, selecting the right reciprocator can significantly impact your production efficiency, coating consistency, and overall product quality. Reciprocators are devices that move spray guns or other coating equipment back and forth in a controlled motion along a fixed path, ensuring even coverage and repeatable results. Choosing between entry-level and advanced reciprocators involves understanding your specific production needs, budget constraints, desired coating precision, and long-term operational goals.

This comprehensive guide explores the key differences between entry-level and advanced reciprocators, helping you make an informed decision for your coating line. We will discuss their features, benefits, limitations, and typical use cases, followed by a series of practical considerations when selecting the right model for your application.

Understanding Reciprocators in Coating Applications

What is a Reciprocator?

A reciprocator is a mechanical device designed to move a spray gun or applicator head in a linear back-and-forth motion across a target surface. This controlled oscillation ensures uniform application of paints, adhesives, varnishes, or other coatings on products moving along a conveyor line or stationary platforms.

Reciprocators are widely used in industries such as automotive, aerospace, furniture manufacturing, and electronics, where consistent coating thickness and finish quality are critical.

Functions and Importance

- Ensures uniform coating thickness: By moving the spray gun evenly, reciprocators eliminate uneven coverage or overspray in certain areas.

- Improves efficiency: Automation reduces manual labor and speeds up the coating process.

- Enhances repeatability: Consistent motion profiles mean every item is coated with the same precision.

- Minimizes material waste: Controlled spraying means less overspray and more efficient use of coating materials.

Entry-Level Reciprocators: Features and Benefits

Overview of Entry-Level Models

Entry-level reciprocators represent the basic, cost-effective solutions for coating operations. They typically feature simplified mechanical and control designs aimed at smaller-scale production or companies new to automated coating.

Common Features

- Manual or basic digital controls: Simple interface with limited programmability or preset speed and stroke adjustments.

- Limited stroke lengths: Usually fixed or adjustable within a narrow range.

- Lower payload capacity: Designed for lighter spray guns or applicators.

- Basic durability: Functional but less rugged for extreme industrial environments.

- Simplified maintenance: Often easier to clean and maintain due to fewer components.

Advantages of Entry-Level Reciprocators

- Cost-effective: Lower initial investment compared to advanced systems.

- Easy to operate: Minimal technical expertise required, suitable for smaller teams.

- Good for simple applications: Meets requirements for consistent coating on straightforward products.

- Quick setup: Fast installation and integration into existing lines.

Limitations of Entry-Level Reciprocators

- Limited flexibility: Often cannot accommodate complex motion profiles or variable speeds.

- Lower precision: May result in less accurate coating thickness control.

- Minimal automation: Lack of advanced sensors or integration with other production systems.

- Restricted scalability: Difficult to upgrade for higher volume or more demanding production environments.

Advanced Reciprocators: Features and Benefits

Overview of Advanced Models

Advanced reciprocators are highly sophisticated machines designed for large-scale operations requiring precise coating control, consistent quality, and extensive automation.

Key Features

- Programmable motion control: Fully adjustable stroke length, speed, dwell times, and acceleration/deceleration profiles.

- High payload capacity: Supports multiple spray guns or heavier applicators.

- Integration capabilities: Can be connected with other automated systems, such as robotic arms, conveyors, and quality control sensors.

- Enhanced durability: Built with industrial-grade components for long service life under heavy use.

- Diagnostic and monitoring tools: Real-time feedback on performance, maintenance needs, and fault detection.

- Multi-axis motion: Some advanced units offer movement beyond simple linear oscillation, including tilt or rotary adjustments for complex coating patterns.

Advantages of Advanced Reciprocators

- Superior coating consistency: High precision control leads to consistent film thickness and quality.

- Customizable profiles: Adapt to varying product sizes, shapes, and coating requirements.

- Automation-friendly: Reduces labor needs and integrates seamlessly with Industry 4.0 environments.

- Higher throughput: Supports faster production speeds without compromising quality.

- Long-term productivity: Durable and low-maintenance design reduces downtime and operating costs.

Potential Drawbacks

- Higher upfront cost: Significant capital investment relative to entry-level models.

- Complexity: Requires skilled operators and maintenance personnel.

- Longer setup: Programming and integration can take time initially.

- Overkill for simple needs: May be unnecessarily sophisticated for small or straightforward applications.

Comparing Entry-Level and Advanced Reciprocators: Important Criteria

Performance and Precision

- Entry-Level: Suitable for standard coating tasks where minor variations are acceptable. Ideal if consistency demands are moderate.

- Advanced: Necessary when specific coating thickness tolerances and uniformity are critical, such as in automotive painting or electronics.

Application Complexity

- Entry-Level: Best for simple, repetitive coating of uniform parts.

- Advanced: Capable of handling complex product designs, different coating types, or mixed production runs.

Production Volume

- Entry-Level: Fits small to mid-volume runs that do not require rapid changeovers.

- Advanced: Supports high-volume, continuous production with frequent adjustments.

Budget Considerations

- Entry-Level: Lower acquisition and maintenance costs make it attractive for budget-conscious operations.

- Advanced: Higher investment but potential savings through reduced waste, improved quality, and labor savings over time.

Maintenance and Support

- Entry-Level: Easier maintenance but may have shorter component life and less support for predictive maintenance.

- Advanced: Requires specialized servicing but typically includes diagnostic tools and remote support.

Use Cases for Entry-Level Reciprocators

Small Workshops and Startups

New companies or small producers with limited budgets benefit from entry-level models to automate basic coating with minimal complexity.

Limited Product Variety

Manufacturers producing uniform product lines where coating requirements do not vary significantly can rely on simple reciprocal motion.

Pilot or Prototype Production

Entry-level systems are useful for testing and development phases before upgrading to higher-end reciprocators.

Use Cases for Advanced Reciprocators

Automotive and Aerospace Industries

High-precision coatings and complex parts necessitate advanced motion control and integration with robotic systems.

Electronics Manufacturing

Delicate components require exact coating thickness and uniformity to ensure function and reliability.

Large-Scale Industrial Production

Facilities running continuous operations with multiple product changes and strict quality standards depend on advanced reciprocators for optimum performance.

Tips for Selecting the Right Reciprocator for Your Line

Assess Your Production Needs

Understand your batch sizes, product complexity, and coating precision requirements upfront.

Evaluate Budget and ROI

Balance initial investment against potential gains in efficiency, waste reduction, and quality improvements.

Consider Future Growth

Choose systems adaptable to scaling production or incorporating new coating techniques.

Ask About Integration

If you plan to automate or digitize your line, confirm that the reciprocator supports communication protocols and sensor interfaces.

Check Service and Support

Opt for manufacturers offering strong technical support, training, and spare parts availability.

Frequently Asked Questions (FAQ)

Q1: Can entry-level reciprocators be upgraded to advanced features later?

A: Some models offer modular upgrades, but often full advanced functionality requires investing in a new system.

Q2: How important is stroke length flexibility?

A: It depends on your product size. Flexible stroke lengths allow for coating different sizes without changing equipment.

Q3: What maintenance is typically required for reciprocators?

A: Regular lubrication, cleaning, and inspection of mechanical parts are common; advanced models also need software updates and diagnostics.

Q4: Are advanced reciprocators compatible with robotic arms?

A: Yes, many advanced systems are designed to integrate with robots for fully automated coating processes.

Q5: How does reciprocator speed affect coating quality?

A: Speed influences how much coating is deposited; too fast can cause thin coverage, too slow can cause buildup and runs.

Conclusion

Selecting between entry-level and advanced reciprocators for your coating line boils down to understanding your specific operational needs, production scale, and quality requirements. Entry-level models offer cost-effective, simple solutions for smaller or less critical applications, while advanced reciprocators provide precision, flexibility, and automation capabilities suited for high-volume, complex manufacturing environments.

By thoroughly evaluating the features, benefits, and constraints of each type, combined with considerations of your budget and future growth plans, you can invest in a reciprocator that maximizes coating uniformity, reduces waste, and enhances overall productivity.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.