Content Menu

● Understanding Spray Booth Systems

>> What Are Conventional Spray Booth Systems?

>> Introduction to Swinger Spray Booth Systems

● Cost Considerations

>> Upfront Investment

>> Operating and Maintenance Costs

>> Energy Consumption

● Benefits of Swinger Spray Booth Systems

>> Enhanced Consistency and Quality

>> Safety Improvements

>> Higher Productivity

● Benefits of Conventional Spray Booth Systems

>> Flexibility

>> Lower Initial Risk

>> Easier Repairs

● Operational Comparison

● When to Choose Swinger Systems

● When to Opt for Conventional Spray Booths

● Environmental and Regulatory Considerations

● Summary and Final Thoughts

● Common Questions About Swinger vs Conventional Spray Booth Systems

Spray booths are essential equipment in many industries for applying coatings efficiently and safely. In this analysis, we will compare swinger spray booth systems and conventional spray booth systems focusing on the costs and benefits associated with each. This comparison will help businesses decide which system best aligns with their production needs, budget, and operational goals.

Understanding Spray Booth Systems

What Are Conventional Spray Booth Systems?

Conventional spray booths are typically fixed enclosures designed for manual or semi-automated spray painting processes. They come in various configurations such as open-face or fully enclosed booths. Conventional booths are commonly used in smaller operations or where flexibility in application style is required. Their technology tends to be simpler with manual control over spraying, airflow, and filtration.

Introduction to Swinger Spray Booth Systems

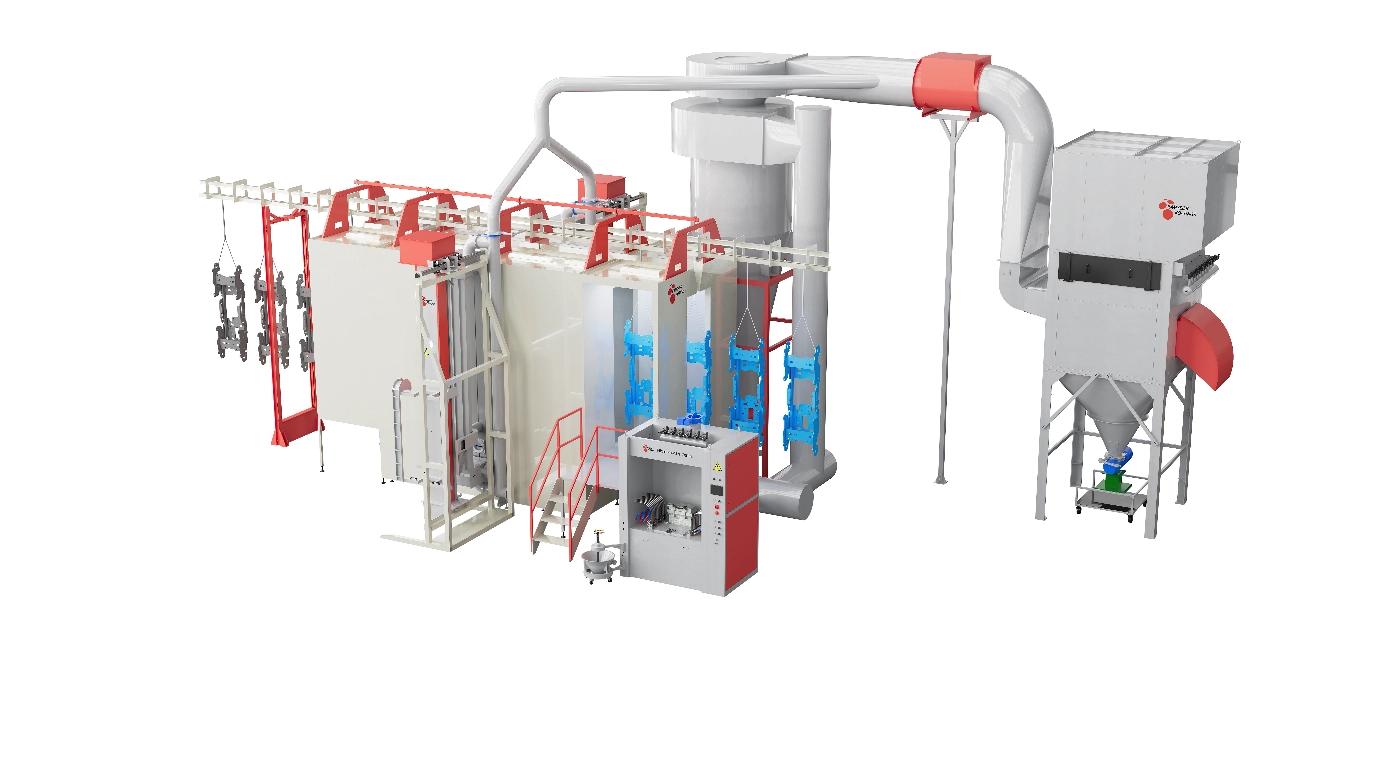

Swinger spray booth systems represent a more automated approach to spray coating. These systems often incorporate robotic arms or automated applicators that swing into position to coat the product uniformly. Swinger systems are engineered for high-volume, consistent production lines where precision and efficiency are critical. Automation reduces human involvement in the spraying process and aims to deliver a more controlled and repeatable finish.

Cost Considerations

Upfront Investment

Conventional spray booths generally require a lower initial investment than swinger systems. Their simpler design and manual operation reduce manufacturing and installation costs. This affordability makes conventional booths appealing for small businesses or startups with limited capital.

On the other hand, swinger booths involve advanced engineering, robotics, and control systems, which raise the upfront purchase and installation expenses. Businesses with the financial capacity and high production demands may justify these initial costs through long-term savings.

Operating and Maintenance Costs

Operating costs for conventional booths can be higher over time due to greater labor involvement and variability in spray precision, which can lead to overspray and wasted materials. Manual processes may also involve more frequent rework and longer cycle times.

Swinger systems, by automating spray application, reduce labor requirements and minimize overspray through consistent, precise coating. Automation also improves throughput speed and reduces the frequency of material waste. However, maintenance costs may be higher due to the complexity of robotic components and control systems requiring specialized servicing.

Energy Consumption

Both systems require ventilation and filtration to maintain air quality and ensure safe operation. Conventional booths may have less efficient airflow control, leading to higher energy consumption. Swinger systems often integrate energy-efficient components and optimized airflow management, lowering ongoing utility expenses.

Benefits of Swinger Spray Booth Systems

Enhanced Consistency and Quality

The automation in swinger booths delivers highly consistent spray patterns and coating thickness. This uniformity results in fewer defects, lower rejection rates, and less rework, improving overall product quality.

Safety Improvements

Since swinger booths reduce the need for manual spraying, workers are less exposed to hazardous fumes and chemicals. This reduces health risks and improves compliance with occupational safety regulations.

Higher Productivity

Automated swinger systems can handle large production volumes with minimal downtime. Their synchronization with production lines and continuous operation capabilities increase output significantly.

Benefits of Conventional Spray Booth Systems

Flexibility

Conventional booths offer more flexibility in handling diverse product sizes and types. Manual control allows operators to adjust spray parameters dynamically for complex or customized jobs.

Lower Initial Risk

The lower upfront cost and simpler technology of conventional booths mean smaller financial risk, particularly for businesses testing new production processes or with fluctuating demand.

Easier Repairs

With simpler mechanical parts, conventional spray booths can often be repaired and maintained without needing specialized technical support, leading to potentially lower service costs.

Operational Comparison

| Feature | Swinger Spray Booth Systems | Conventional Spray Booth Systems |

| Initial Cost | High | Low |

| Labor Requirements | Low (automated) | High (manual) |

| Spray Precision | Very High | Variable |

| Material Waste | Low | Higher |

| Maintenance Complexity | High (robotic systems) | Low |

| Energy Efficiency | High | Moderate to Low |

| Flexibility | Limited to specific product sizes/shapes | High flexibility |

| Safety | Enhanced worker safety | Standard safety precautions |

| Production Volume | Suitable for high-volume continuous runs | Suitable for low to medium volumes |

| Customization for Jobs | Less flexible due to automation | Highly flexible |

When to Choose Swinger Systems

Swinger spray booth systems are ideal for manufacturers who:

- Operate large-scale, high-volume production lines.

- Require consistent finish quality with minimal defects.

- Seek to reduce labor costs and improve workplace safety.

- Can afford a higher upfront investment with a long-term outlook.

- Need automated solutions that integrate seamlessly with other production line equipment.

When to Opt for Conventional Spray Booths

Conventional spray booths better suit businesses that:

- Have smaller or variable production runs.

- Require flexible operation for diverse product types.

- Need to maintain a lower initial capital expenditure.

- Can manage higher labor involvement without impacting costs significantly.

- Prefer simpler equipment with easier maintenance.

Environmental and Regulatory Considerations

Both systems must comply with environmental regulations concerning emissions and waste. Swinger systems' precision reduces overspray and volatile organic compound emissions, benefiting environmental footprint and regulatory compliance. Conventional booths may struggle with overspray control, increasing waste and emission management costs.

Summary and Final Thoughts

In summary, swinger spray booth systems, while demanding a higher initial investment and maintenance complexity, offer significant benefits in automation, efficiency, safety, and product quality. They are particularly suited for high-volume industrial operations seeking to lower long-term costs and improve consistency.

Conventional spray booths remain relevant for smaller or diversified operations where flexibility, lower upfront cost, and ease of maintenance are prioritized despite potentially higher labor and material usage costs.

A cost-benefit analysis should factor in production volume, budget constraints, quality requirements, labor availability, and long-term operational goals. Selecting the right system depends on balancing these factors against the expected return on investment, operational efficiency, and safety.

Common Questions About Swinger vs Conventional Spray Booth Systems

Q1: Which spray booth system is more cost-effective in the long run?

A1: Swinger systems, despite higher upfront costs, generally offer better long-term cost-effectiveness due to reduced labor, less material waste, and higher productivity.

Q2: Are swinger spray booths suitable for small businesses?

A2: Typically, swinger booths are designed for high-volume production and may not be cost-effective or flexible enough for small operations, where conventional booths are preferred.

Q3: How does worker safety compare between the two systems?

A3: Swinger systems reduce operator exposure to hazardous sprays through automation, offering enhanced safety compared to manual spraying in conventional booths.

Q4: Do conventional booths require more maintenance?

A4: Conventional booths are generally easier and less expensive to maintain due to their simpler mechanical design, whereas swinger booths need specialized maintenance for their robotic components.

Q5: Can swinger systems handle diverse product shapes and sizes?

A5: Swinger systems are less flexible because automation is often configured for specific product dimensions, while conventional booths accommodate a wider range of product variability.

[1] https://www.spraysystems.com/how-automated-spray-booth-systems-can-save-you-time-and-money/

[2] https://pdfcoffee.com/-5845-pdf-free.html

[3] https://masterflo-uk.com/new-vs-used-spray-booths-pros-cons/

[4] https://huggingface.co/facebook/xm_transformer_unity_hk-en/commit/e37fd5ab9c6faf7a9547972cf6dace1c144c49c8.diff?file=en_zh_spm.dict

[5] https://rollitbooths.com/collapsible-spray-booth-vs-fixed-enclosure/

[6] https://huggingface.co/openbmb/cpm-bee-1b/commit/bd72a61dd7a59086ed7456f1dfcaa995c8ec58a3.diff

[7] https://www.ramseierkoatings.com/swinger-vs-traditional-powder-coating-systems-which-one-fits-your-needs.html

[8] https://www.ramseierkoatings.com/comparing-swinger-and-manual-spray-booths-which-offers-better-control.html

[9] http://saicozero.com/understanding-spray-booth-ventilation-systems/

[10] https://globalfinishing.com/2019/08/21/woodworking-paint-booths-choosing-between-open-face-enclosed-spray-booths/

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.