Content Menu

● Understanding the Basics of Swinger and Manual Spray Booths

>> What is a Swinger Spray Booth?

>> What is a Manual Spray Booth?

● Control in Swinger Spray Booths

>> Automated Precision and Consistency

>> Limitations in Fine-Tuned Control

● Control in Manual Spray Booths

>> Direct and Dynamic Operator Control

>> Factors Affecting Operator Control

● Comparison of Spray Guns in Manual and Swinger Booth Systems

>> Manual Spray Guns: Features and Benefits

>> Swinger Booth Spray Mechanisms

● Advantages and Disadvantages: Which Offers Better Control?

● Safety and Environmental Considerations

>> Swinger Booths

>> Manual Booths

● When to Choose Swinger or Manual Spray Booths?

>> Swinger Spray Booths Are Ideal For:

>> Manual Spray Booths Are Better Suited For:

● Frequently Asked Questions (FAQ)

Spray booths are essential equipment in industries requiring precision application of coatings like paints, powders, and other finishes. Among the various types of spray booths and spray systems, two common types often discussed are swinger spray booths and manual spray booths. Each system offers distinct advantages and drawbacks, particularly when it comes to the degree of control they provide during application. This article explores in detail how swinger and manual spray booths compare, focusing on control, efficiency, safety, and precision.

Understanding the Basics of Swinger and Manual Spray Booths

What is a Swinger Spray Booth?

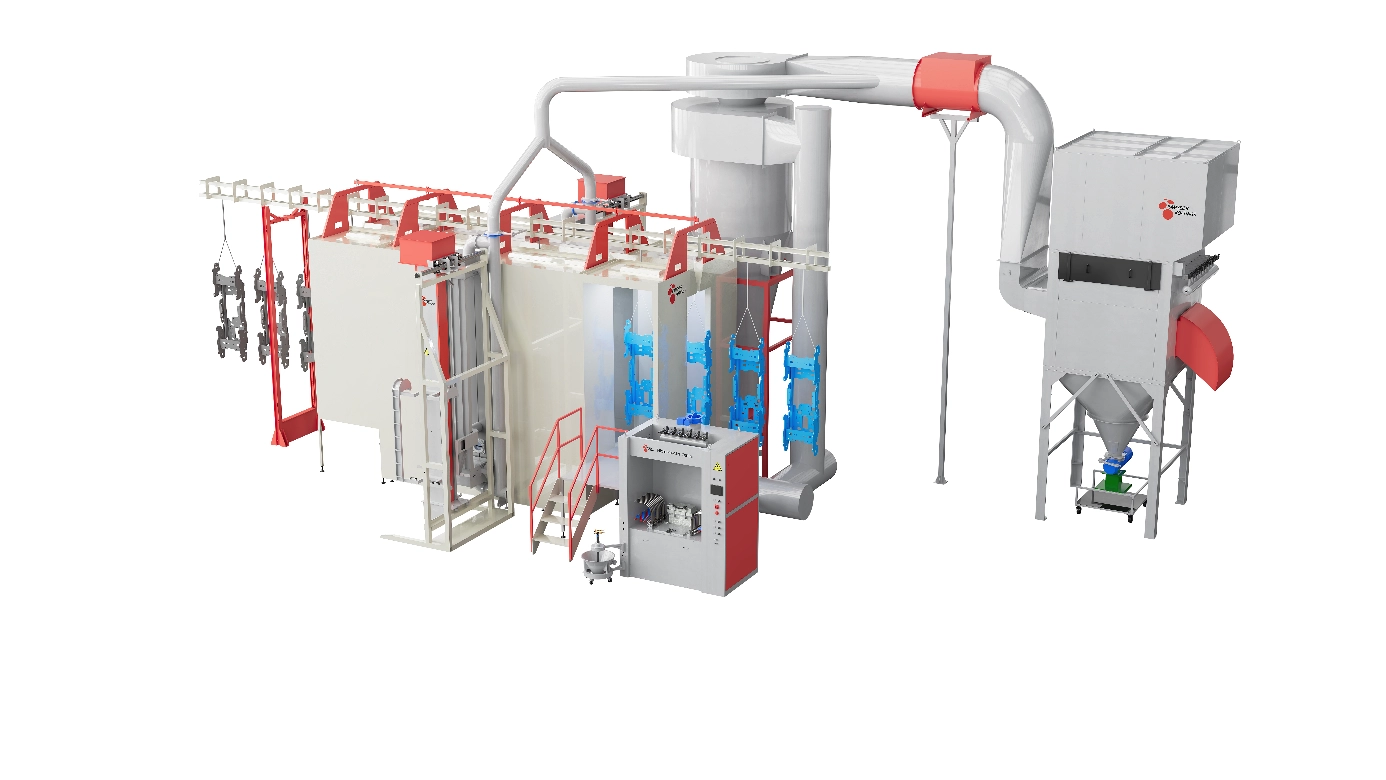

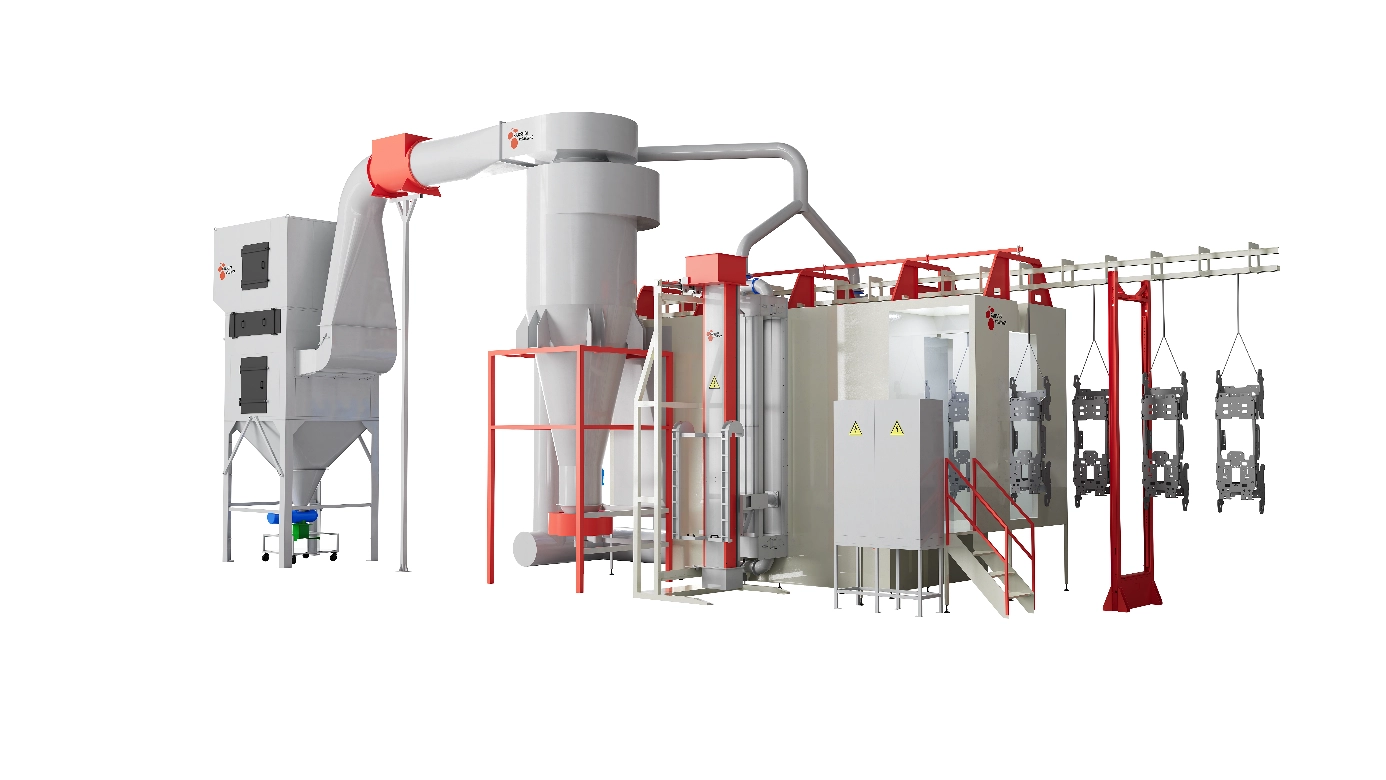

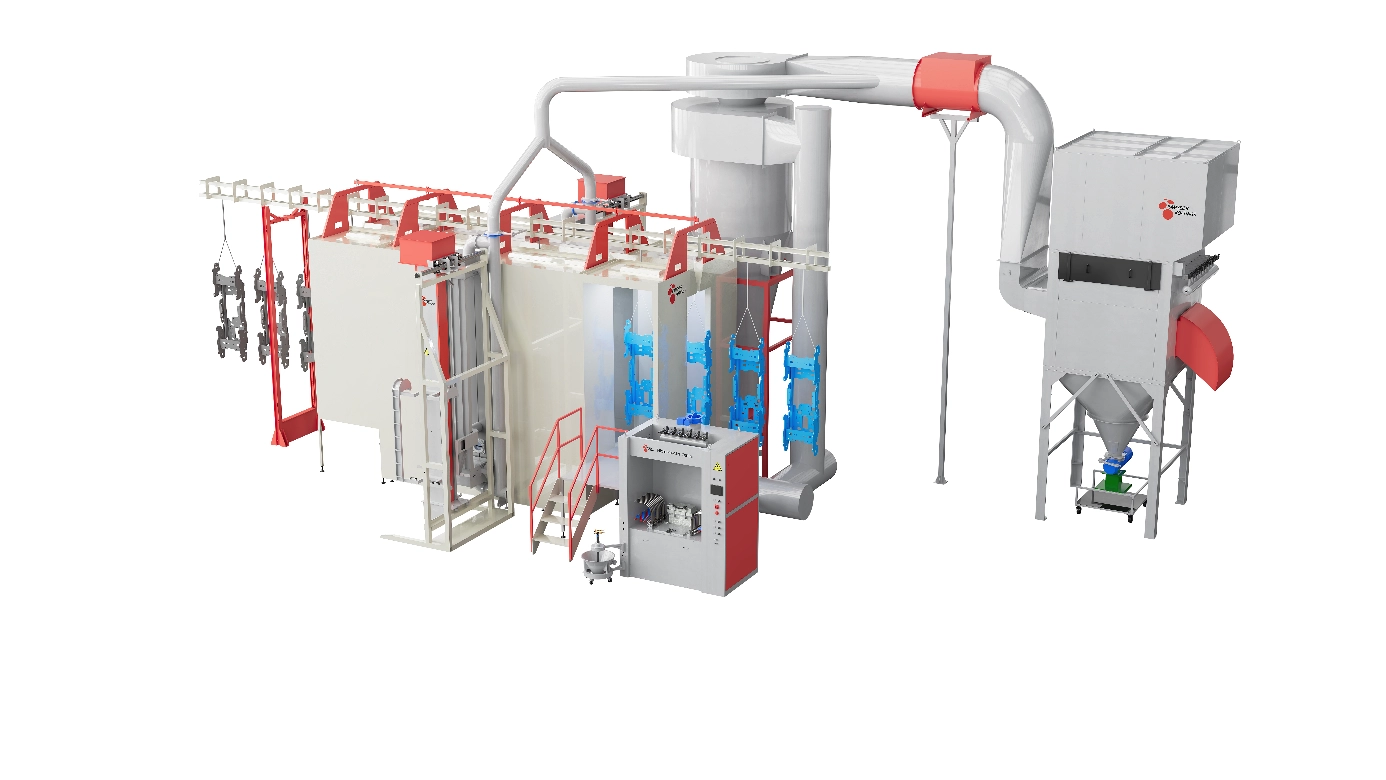

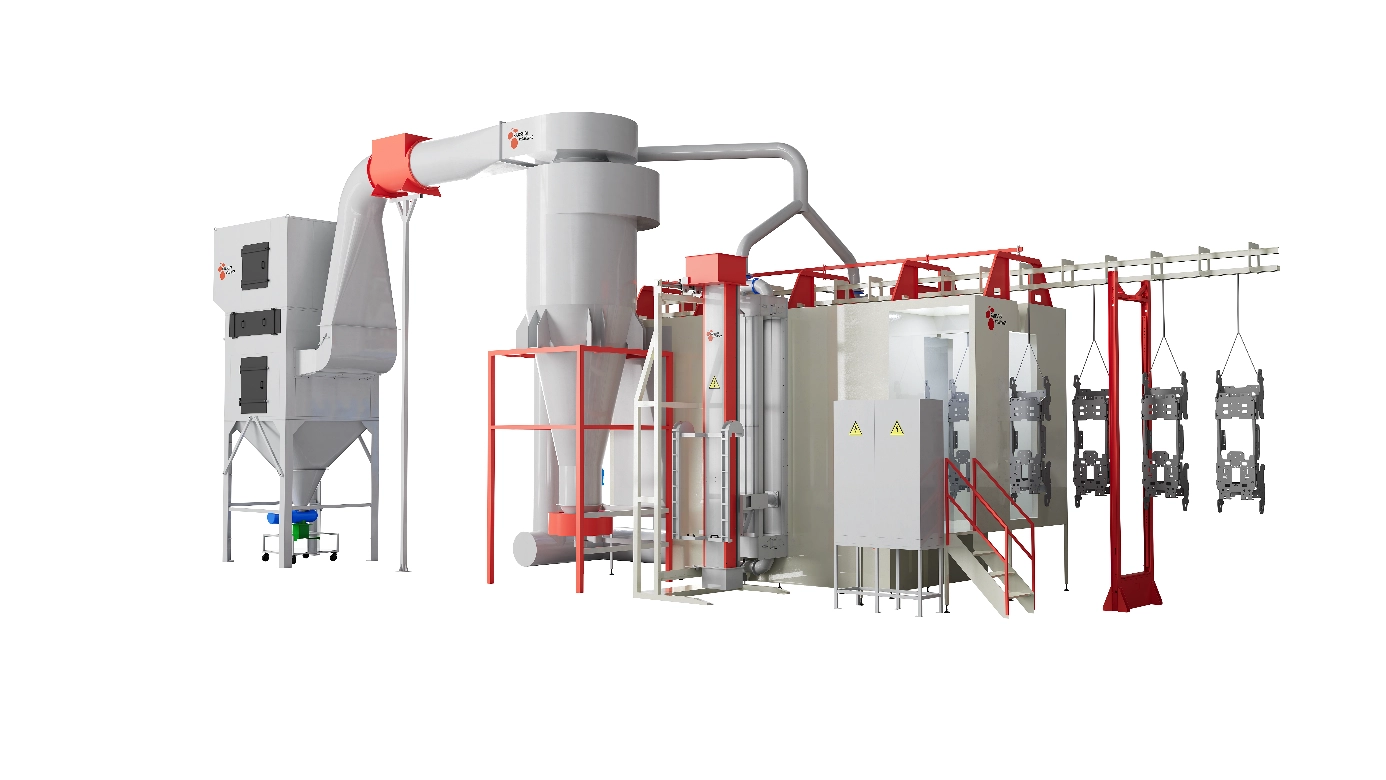

A swinger spray booth typically refers to an automated or semi-automated system where the spray guns or the object being coated is mechanically swung or rotated to ensure an even coating over complex shapes. This technology is widely used in powder coating and other finishing processes to increase throughput and reduce human variability.

Key features of swinger spray booths include:

- Automated rotation or swinging mechanisms to apply finishes evenly around an object.

- Fixed spray jets or guns strategically positioned to cover all angles.

- Mechanisms designed to minimize overspray and reuse unused materials, helping reduce waste.

- Built-in systems for ventilation, drying, and mist extraction that improve work environment safety.

Swinger spray booths are commonly used in high-volume industrial settings where consistency and speed are critical.

What is a Manual Spray Booth?

A manual spray booth is a controlled environment designed for operators who manually apply coatings using handheld spray guns. Operators have direct interaction with the spray application process, controlling the spray pattern, flow, and positioning dynamically.

Key elements of manual spray booths include:

- A confined and ventilated space that captures overspray and protects workers.

- Use of manual spray guns where operators can adjust air pressure, fluid flow rate, and spray pattern.

- Flexibility to coat varied surfaces and complex shapes that automated systems may struggle with.

- Emphasis on safety with mandatory personal protective equipment, including respirators and eye protection.

Manual spray booths are often preferred for specialized jobs, small production runs, and touch-ups.

Control in Swinger Spray Booths

Automated Precision and Consistency

Swinger spray booths excel at delivering uniform coatings by automating the spray application and object movement processes. The system is designed to:

- Rotate or swing parts in front of fixed spray nozzles, preventing missed areas.

- Provide adjustable spray pressure and timing controlled by the system's programming to create an even finish.

- Reduce operator variability by automating key steps.

The pre-programmed nature of these booths often guarantees repeatable results, improving quality control for large batches.

Limitations in Fine-Tuned Control

Despite offering consistent coverage, swinger spray booths offer limited on-the-fly control during the spray process because the operator's interaction is minimized. The system parameters are set before spraying, and adjustments mid-process are generally not possible without stopping the operation.

While the booths include adjustable settings during setup, they may be less adaptable for unique or complex items without manual intervention.

Control in Manual Spray Booths

Direct and Dynamic Operator Control

Manual spray booths offer unmatched control to the operator, who can:

- Adjust the spray pattern shape, fluid flow rate, and air pressure rapidly using the spray gun controls.

- Direct the spray exactly where needed, including intricate or hard-to-reach areas.

- Vary movement speed and distance from the surface dynamically, adapting to surface conditions and shape.

This direct control allows skilled operators to deliver highly precise coatings that can match diverse application needs, producing smoother finishes.

Factors Affecting Operator Control

The overall effectiveness of manual spray booths depends heavily on:

- Operator skill and experience, which impacts the consistency and quality of the finish.

- The ergonomic design of spray guns, offering intuitive and responsive controls.

- The ability to adjust settings on the fly using digital models or traditional knobs.

However, operators must remain vigilant to prevent issues like overspray or uneven layers, which are more common than in automated systems.

Comparison of Spray Guns in Manual and Swinger Booth Systems

Manual Spray Guns: Features and Benefits

Manual spray guns within spray booths provide:

- A trigger mechanism allowing precise start and stop of coating flow.

- Controls to fine-tune air pressure, flow rate, and spray pattern, enabling custom application.

- Portability, simplicity, and versatility to apply a wide variety of coatings (paints, stains, powders).

- Cost-effectiveness and straightforward maintenance due to their simple construction.

Operators benefit from the ability to customize complete finishes, making manual guns ideal for custom jobs and repairs.

Swinger Booth Spray Mechanisms

Swinger booths use stationary spray jets arranged in 360° arrays around the object. These jets:

- Deliver a mist of coating simultaneously over the surface.

- Operate at consistent pressures to optimize coating deposition.

- Eliminate the need for moving parts that operators manually handle, reducing injury risks.

- Include exhaust and drying modes for efficiency and worker safety.

While spray jets maximize coverage uniformly, the lack of manual adjustment during spraying reduces flexibility.

Advantages and Disadvantages: Which Offers Better Control?

| Aspects | Swinger Spray Booth | Manual Spray Booth |

| Control Precision | Automated, consistent, repeatable | Dynamic, adaptable, reliant on skill |

| Flexibility | Limited to preset programs and shapes | High adaptability to complex shapes |

| User Interaction | Minimal operator interaction | Full operator control of spray parameters |

| Risk of Overspray | Reduced by system design and recovery | Higher; dependent on operator technique |

| Speed & Throughput | High efficiency for batch production | Slower, better for small runs or touch-ups |

| Maintenance | More complex due to mechanical parts | Simple and easy to maintain |

| Safety | System enclosed and ventilated; less exposure | Operator must wear protective gear |

Safety and Environmental Considerations

Both swinger and manual spray booths are designed with worker safety and environmental impact in mind, but their approaches differ.

Swinger Booths

- Feature advanced ventilation and mist extraction systems to minimize airborne particles.

- Often include filters and powder reclaim mechanisms to reduce material waste and environmental contamination.

- Automation reduces operator exposure to hazardous materials.

Manual Booths

- Require strict adherence to personal protective equipment protocols (respirators, gloves, eye protection).

- Overspray can be higher if the operator is inexperienced.

- Booth design focuses on containment and filtration of the overspray but depends heavily on proper use.

When to Choose Swinger or Manual Spray Booths?

Swinger Spray Booths Are Ideal For:

- High-volume production lines.

- Tasks demanding high uniformity and repeatability.

- Environments where minimizing operator risk is a priority.

- Projects that benefit from reclaiming unused coatings.

Manual Spray Booths Are Better Suited For:

- Small batch or prototype production.

- Complex or irregular surfaces requiring delicate attention.

- Situations where variable, customized coatings are needed.

- Jobs requiring portability and quick touch-ups.

Frequently Asked Questions (FAQ)

1. What is the main difference between swinger and manual spray booths in terms of control?

Swinger booths offer automated, consistent control with limited on-the-fly adjustments, while manual booths provide operators direct, dynamic control to adapt spray parameters in real time.

2. Can a manual spray booth reduce overspray as effectively as a swinger booth?

Manual spray booths rely heavily on operator skill to minimize overspray, whereas swinger booths use fixed spray jets and reclaim systems to reduce waste more consistently.

3. Are swinger spray booths safer for operators compared to manual booths?

Generally, yes. Swinger booths reduce operator exposure to hazardous materials by automating spraying within enclosed, ventilated spaces, whereas manual booths require operators to wear protective gear and be cautious.

4. Which spray booth is more cost-effective for small operations?

Manual spray booths are typically more cost-effective for small operations due to their lower equipment cost and flexibility in handling varied tasks.

5. Can manual spray guns handle a wider variety of coatings than swinger booth systems?

Yes. Manual spray guns offer versatility in applying different coatings, including paints, stains, powder coatings, and lacquers, making them suitable for diverse applications.

[1] https://www.codinter.com/en/manual-spray-guns-a-complete-guide/

[2] https://anyflip.com/aybqz/xhpg/basic

[3] https://www.ramseierkoatings.com/swinger-vs-traditional-powder-coating-systems-which-one-fits-your-needs.html

[4] https://patents.google.com/patent/US20030094509A1/en

[5] https://www.ramseierkoatings.com/is-an-automatic-spray-booth-system-more-efficient-than-a-manual-one.html

[6] https://patents.google.com/patent/WO2019037799A1/zh

[7] https://jmcautomotiveequipment.com/blog/downdraft-vs-side-down-draft-vs-cross-draft-paint-booths/

[8] https://www.diva-portal.org/smash/get/diva2:18241/fulltext01

[9] https://pfsspraybooths.com/the-ultimate-paint-booth-usage-guide-for-perfect-results

[10] https://patents.google.com/patent/CN102794245A/zh

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.