Content Menu

● Introduction

● What Is a Manual Spray Booth System?

>> Key Components of Manual Spray Booth Systems

● Why Choose Manual Spray Booth System Suppliers?

>> Benefits of Working with Specialized Suppliers

● Advantages of Manual Spray Booth Systems

>> Improved Safety

>> Superior Finish Quality

>> Reduced Waste and Cleaner Workspace

>> Increased Productivity and Flexibility

>> Regulatory Compliance

● Types of Manual Spray Booth Systems

● How to Select the Right Manual Spray Booth System Supplier

>> Key Considerations

● Customization and OEM Services for Global Markets

● The Manufacturing Process: From Design to Delivery

● Frequently Asked Questions About Manual Spray Booth System Suppliers

>> Q1: What are the main benefits of using a manual spray booth system?

>> Q2: Can manual spray booth systems be customized for different industries?

>> Q3: What should I consider when choosing a manual spray booth system supplier?

>> Q4: How long does it take to manufacture and install a custom manual spray booth system?

>> Q5: Are OEM and private label services available for international buyers?

● Conclusion

● Citations:

Introduction

Manual spray booth systems are essential for achieving high-quality finishes in a wide range of industries, from automotive and furniture to aerospace and metal fabrication. As global demand for efficient, safe, and customizable coating solutions grows, the role of *Manual Spray Booth System Suppliers* becomes increasingly critical. This comprehensive guide explores the features, benefits, customization options, and key considerations when selecting a manual spray booth system supplier, especially for international OEM, wholesale, and brand partnerships.

---

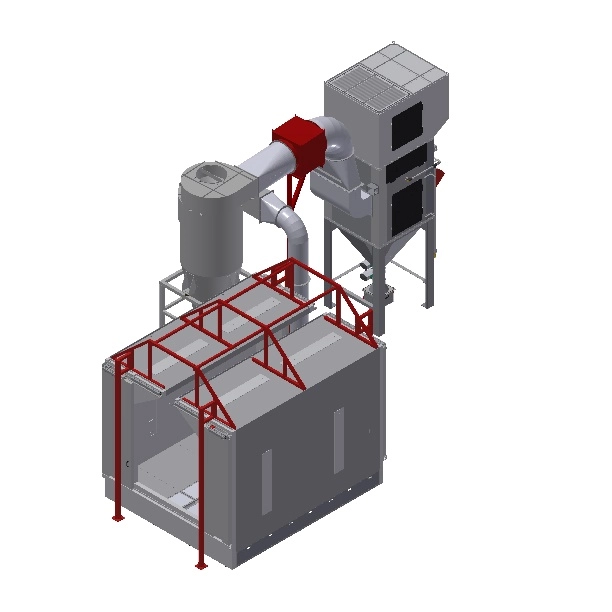

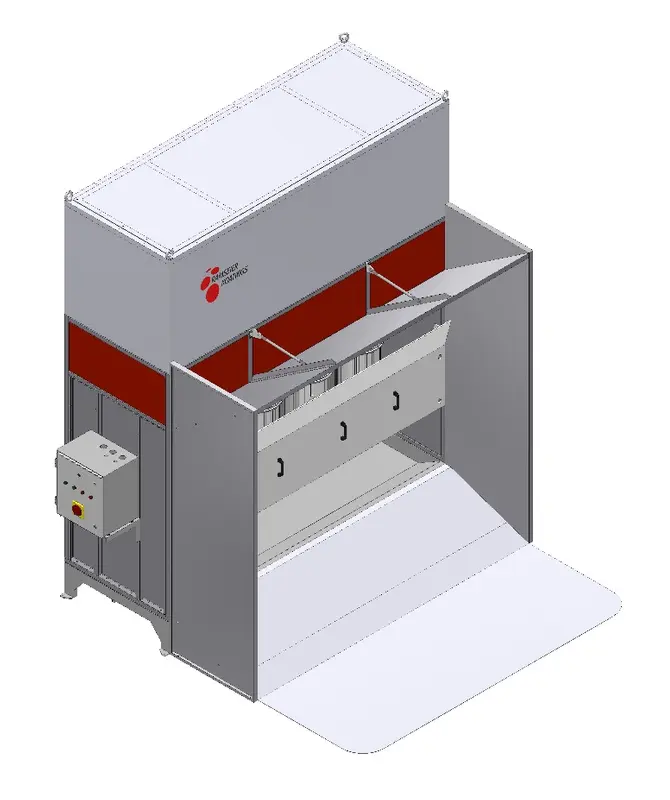

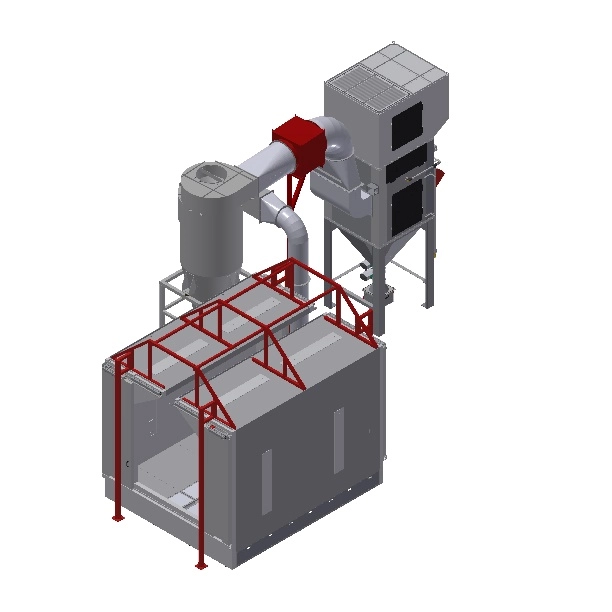

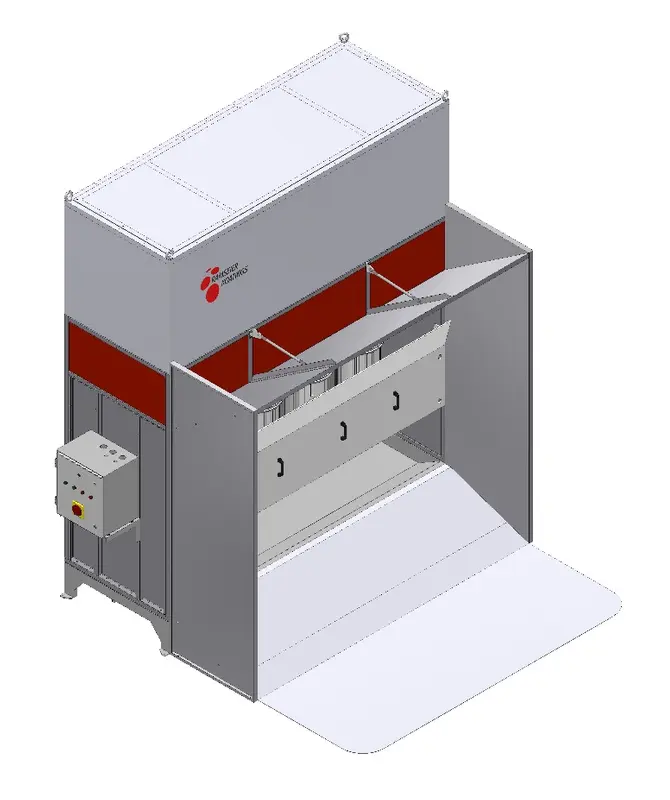

What Is a Manual Spray Booth System?

A manual spray booth system is an enclosed workspace designed for the application of paints, powders, or other coatings by hand, using spray guns or powder applicators. Unlike automated systems, manual booths rely on skilled operators for precise coating application. These systems are widely used for small-batch production, custom jobs, or when flexibility and control over the finishing process are required[3][4].

Key Components of Manual Spray Booth Systems

- Booth Enclosure: Made from metal or plastic panels, providing a controlled environment and containing overspray[4].

- Ventilation and Filtration: Powerful fans and multi-stage filters remove paint particles, fumes, and contaminants, ensuring safety and air quality[2][8].

- Lighting: Integrated lighting ensures visibility and quality control during application[2].

- Control Systems: Panels for adjusting airflow, temperature, and other parameters[2].

- Powder Feed System (for powder coating): Delivers coating material from the hopper to the spray gun[4].

- Curing Oven (for powder coating): Hardens the applied powder for a durable finish[4].

---

Why Choose Manual Spray Booth System Suppliers?

Benefits of Working with Specialized Suppliers

- Customization: Leading suppliers offer tailored designs to fit specific workspace, product size, and production volume requirements[6][13].

- Compliance: Suppliers ensure booths meet local and international safety and environmental regulations[6][8].

- OEM/ODM Services: Many suppliers provide OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer) services for branding and private label needs.

- Technical Support: Ongoing consultation, installation, and after-sales support.

- Cost Efficiency: Competitive pricing for bulk orders and long-term partnerships.

---

Advantages of Manual Spray Booth Systems

Improved Safety

Manual spray booth systems protect workers from hazardous fumes, dust, and overspray, reducing health risks and ensuring compliance with safety standards[2][8][10].

Superior Finish Quality

A controlled, dust-free environment eliminates contaminants, resulting in smoother, more consistent coatings and fewer defects[2][12].

Reduced Waste and Cleaner Workspace

Efficient filtration and airflow minimize overspray and material waste, keeping the workspace clean and reducing cleanup time[2][8].

Increased Productivity and Flexibility

Manual systems allow for quick changeovers, making them ideal for small batches, custom jobs, and frequent color changes[3][4].

Regulatory Compliance

Properly designed spray booths help businesses comply with OSHA, NFPA, EPA, and other regulations, avoiding fines and operational disruptions[8].

---

Types of Manual Spray Booth Systems

| Type | Description | Best For |

| Wet Paint Spray Booths | For solvent or water-based liquid paints. | Automotive, furniture, metalwork |

| Manual Powder Coating Booths | For electrostatic powder application, with powder recovery systems34. | Metal fabrication, appliances |

| Down Draft Booths | Airflow directed downward to protect operators from hazardous particles4. | Hazardous or fine powder spraying |

| Batch Booths | Process multiple items simultaneously4. | Medium-volume production |

| Portable/Modular Booths | Retractable or mobile booths for flexible workspace use711. | Limited space, changing workflows |

---

How to Select the Right Manual Spray Booth System Supplier

Key Considerations

1. Customization Capability

Choose suppliers who can tailor booth size, airflow, filtration, and layout to your specific needs. Over 50% of booths sold are customized to fit unique requirements[5][13].

2. Material Quality and Construction

Ensure the supplier uses durable, nonflammable materials and explosion-proof fixtures for safety and longevity[2][7].

3. Regulatory Compliance

Verify that the supplier's systems meet all relevant safety and environmental standards in your country or region[6][8].

4. Technical Support and Lead Time

Assess the supplier's ability to provide installation, training, and after-sales service. Ask about manufacturing and delivery timelines—custom booths may take 8–12 weeks to produce and install[7][11].

5. OEM/ODM and Branding Services

For international platforms, prioritize suppliers with experience in OEM/ODM, private labeling, and bulk export.

---

Customization and OEM Services for Global Markets

Manual Spray Booth System Suppliers often offer comprehensive OEM services, including:

- Design Adaptation: Adjusting booth dimensions, airflow, and filtration for different industries and regulations.

- Branding: Private label options for overseas distributors, wholesalers, and brand owners.

- Documentation: Providing compliance certificates, manuals, and installation guides in multiple languages.

- Bulk Production: Scalable manufacturing to meet large order quantities.

---

The Manufacturing Process: From Design to Delivery

1. Design and Engineering: Detailed planning based on customer specifications, product size, and production needs[4].

2. Material Procurement: Sourcing high-grade metals, plastics, and electrical components.

3. Fabrication: Precision cutting, welding, and assembly of booth panels and frames.

4. Electrical and Control System Integration: Installing wiring, control panels, and safety features.

5. Filtration and Ventilation Installation: Ensuring optimal airflow and contaminant removal.

6. Quality Inspection: Rigorous testing for safety, performance, and compliance.

7. Packing and Shipping: Secure packaging for international delivery, with clear assembly instructions[4].

---

Frequently Asked Questions About Manual Spray Booth System Suppliers

Q1: What are the main benefits of using a manual spray booth system?

A1: Manual spray booth systems offer improved safety, higher finish quality, reduced material waste, a cleaner workspace, and compliance with safety and environmental regulations[2][8][10].

Q2: Can manual spray booth systems be customized for different industries?

A2: Yes, leading suppliers offer extensive customization options, including booth size, airflow, filtration, and layout, to meet the unique needs of various industries such as automotive, furniture, and aerospace[5][6][13].

Q3: What should I consider when choosing a manual spray booth system supplier?

A3: Consider the supplier's experience, customization capabilities, compliance with regulations, technical support, OEM/ODM services, and delivery timelines[6][7][11].

Q4: How long does it take to manufacture and install a custom manual spray booth system?

A4: Manufacturing and installation typically take 8–12 weeks for custom orders, depending on complexity and supplier capacity[7][11].

Q5: Are OEM and private label services available for international buyers?

A5: Many manual spray booth system suppliers provide OEM/ODM and private label services, including branding, documentation, and bulk production for overseas distributors and brands.

---

Conclusion

Manual spray booth system suppliers play a vital role in supporting global manufacturing and finishing industries. By offering high-quality, customizable, and compliant solutions, these suppliers enable businesses to achieve superior coating results, maintain safety, and meet regulatory requirements. Whether you are an OEM, wholesaler, or brand owner seeking reliable partners for international markets, selecting the right manual spray booth system supplier is key to your success.

Citations:

[1] https://www.ramseierkoatings.com/manual-spray-booth-system-distributor-the-ultimate-guide-for-industrial-coating-solutions.html

[2] https://www.codinter.com/en/spray-booths-a-complete-guide/

[3] https://www.nordson.com/en/products/industrial-coating-systems-products/manual-powder-coating-booth

[4] https://ems-powdercoating.com/manual-powder-coating-booth/

[5] https://www.paint-booths.com/FAQS.html

[6] https://www.spraysystems.com/questions-to-address-when-purchasing-a-spray-booth/

[7] https://duroair.com/blog/questions-qualifying-industrial-paint-booth-manufacturers/

[8] https://www.hppneumatics.com/spray-booth-benefits/

[9] https://www.usius.com/essential-questions-to-ask-your-paint-booth-supplier/

[10] https://www.ramseierkoatings.com/what-are-the-top-benefits-of-using-manual-spray-booth-systems.html

[11] https://www.duroair.com/blog/questions-qualifying-industrial-paint-booth-manufacturers

[12] https://www.ramseierkoatings.com/what-are-the-top-advantages-of-manual-spray-booths-in-custom-painting-projects.html

[13] https://www.toolsusa.com/FAQS.html

[14] https://www.thomasnet.com/suppliers/usa/spray-booths-6943005

[15] https://www.fauxhammer.com/top-10/best-airbrush-extractor-spray-booth-for-miniature-painters/

[16] https://www.spraysystems.com/nfpa-33/

[17] https://www.tungsten.com/blog/the-spray-booth

[18] https://paintline.com/products/pjsb

[19] https://reliantfinishingsystems.com

[20] https://www.thomasnet.com/suppliers/usa/spray-booth-equipment-77063600

[21] https://totalfinishingsupplies.com/products/manual-control-panel-for-tfs-paint-spray-booth-ul-listed

[22] https://globalfinishing.com/wp-content/uploads/2020/07/General_Industrial_Booth_Owner_Manual.pdf

[23] https://www.iqsdirectory.com/articles/paint-finishing-equipment/paint-spray-booths.html

[24] https://www.wagner-group.com/en/industry/products/powder-coating/booths/

[25] https://www.spraysystems.com/wp-content/uploads/2015-Presentation-Paper-Spray-Booth-Essentials.pdf

[26] https://globalfinishing.com/2019/06/12/understanding-key-components-of-paint-booth-design/

[27] https://cakesafe.com/products/SPRAY-BOOTH-FAQS-c145403013

[28] https://forum.finescale.com/t/spray-booth-question/250541

[29] https://pittsburghsprayequip.com/blogs/pittsburgh-spray-equipment-company/common-paint-booth-problems-and-how-to-fix-them

---

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.