Content Menu

● Understanding Automatic Spray Booth Systems

● Why Choose Automatic Spray Booth Systems?

● Top Industries Benefiting from Automatic Spray Booth Systems

>> Automotive Industry

>>> Applications

>>> Advantages

>> Aerospace Industry

>>> Applications

>>> Advantages

>> Electronics Industry

>>> Applications

>>> Advantages

>> Furniture and Woodworking

>>> Applications

>>> Advantages

>> Industrial Manufacturing

>>> Applications

>>> Advantages

>> Commercial Vehicles and Semis

>>> Applications

>>> Advantages

>> Appliance Manufacturing

>>> Applications

>>> Advantages

>> Metalworking and Plastics

>>> Applications

>>> Advantages

>> Food and Beverage Industry

>>> Applications

>>> Advantages

● How to Select the Right Automatic Spray Booth System

>> Assessing Production Needs

>> Choosing the Right Configuration

>> Integration with Existing Operations

● Future Trends in Automatic Spray Booth Systems

>> Advanced Robotics and AI

>> Sustainable Practices

>> Digitalization and Industry 4.0

● Frequently Asked Questions

● Citations:

Automatic spray booth systems have revolutionized the way industries approach surface finishing, coating, and painting. By integrating advanced robotics and automation, these systems deliver consistent quality, maximize efficiency, and enhance workplace safety. But which industries stand to benefit the most from this technology? This comprehensive article explores the top sectors where automatic spray booth systems make the biggest impact, delving into their specific applications, advantages, and future trends.

Understanding Automatic Spray Booth Systems

What Are Automatic Spray Booth Systems?

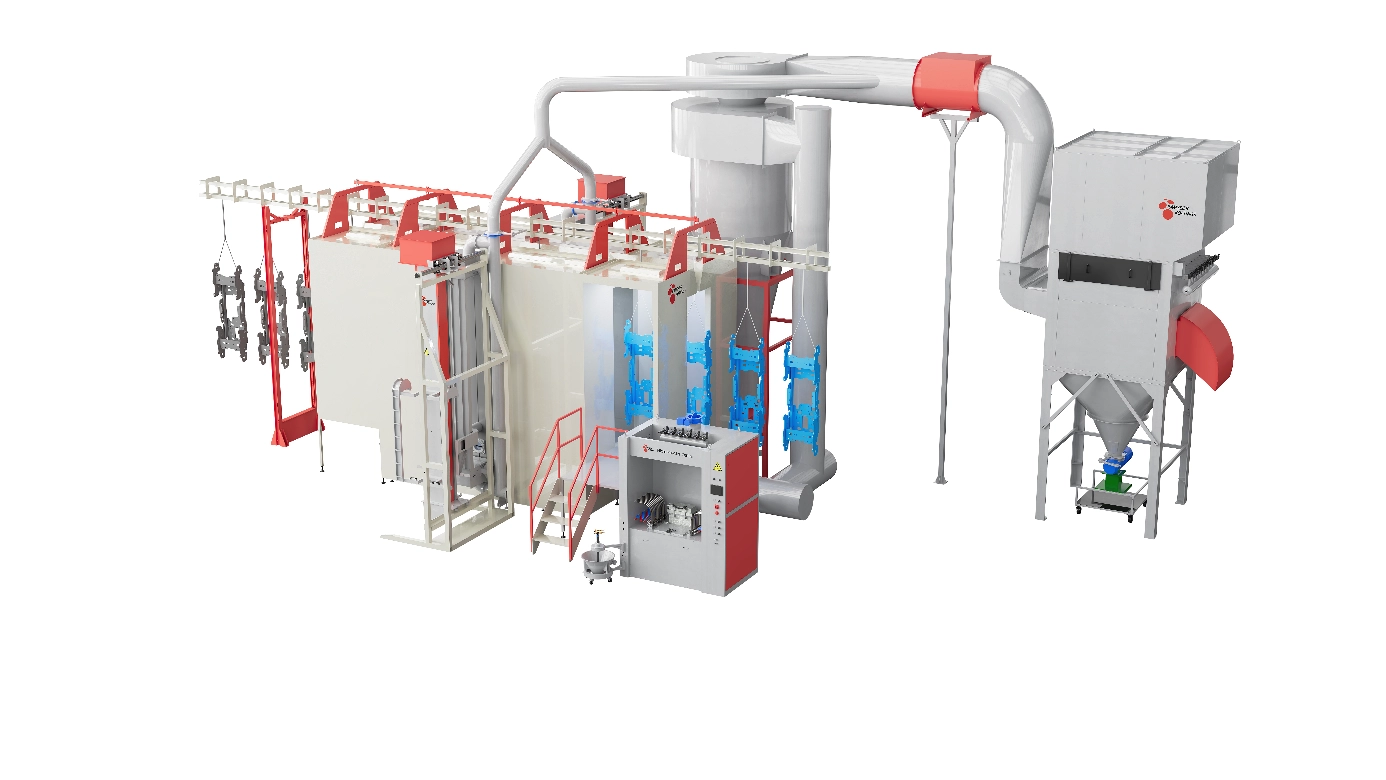

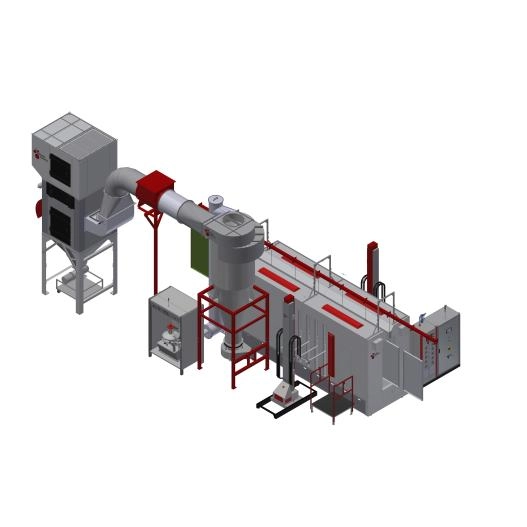

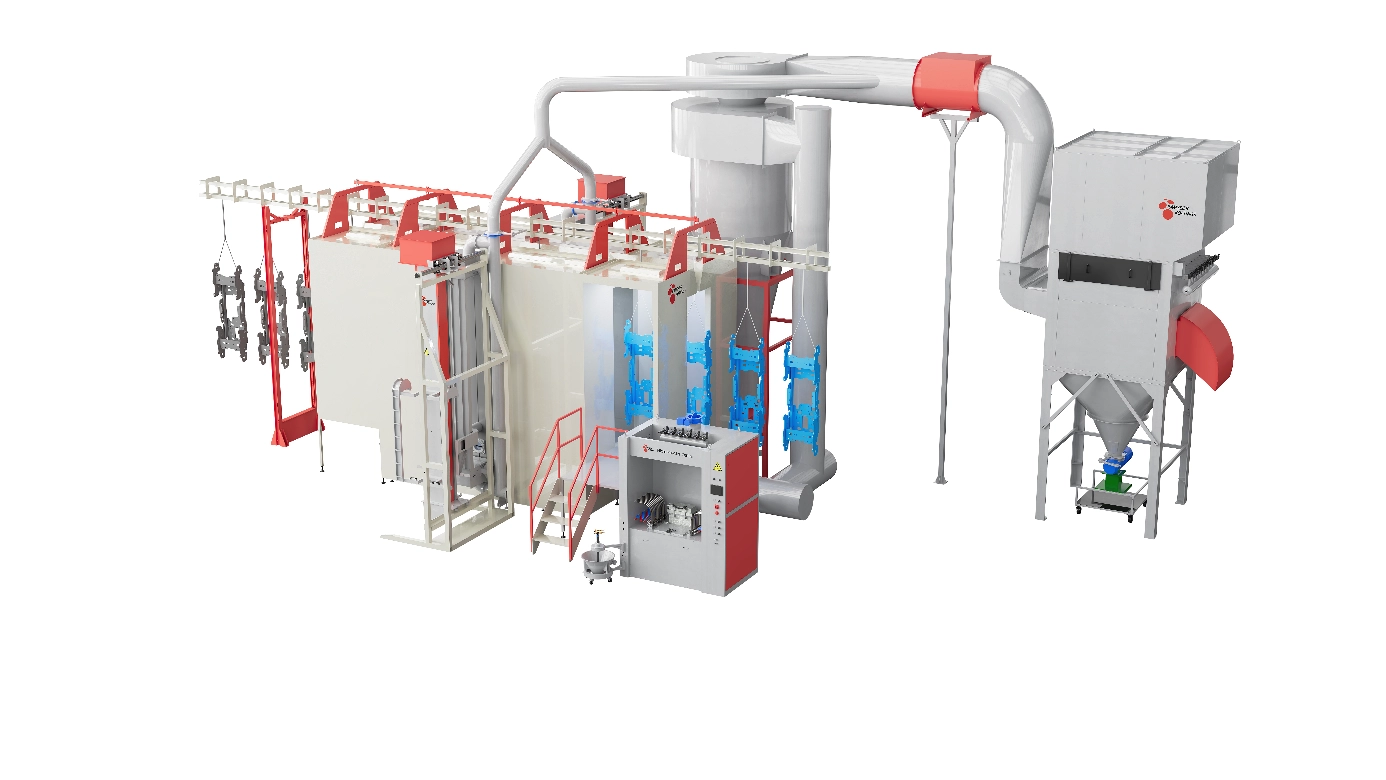

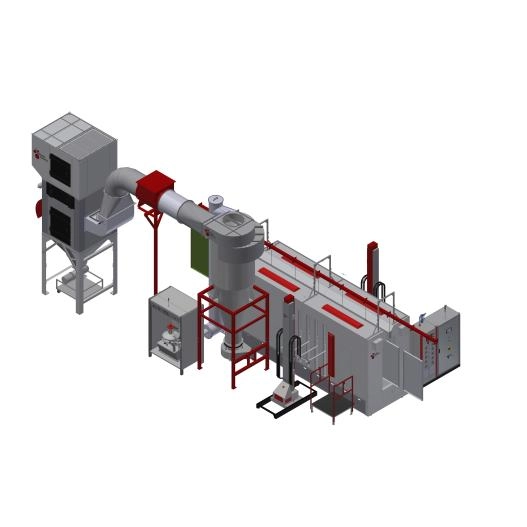

Automatic spray booth systems are enclosed environments equipped with robotic arms or automated machinery that apply coatings, paints, or finishes to products and components. These systems are designed to control variables such as temperature, humidity, air flow, and overspray, ensuring optimal coating conditions and worker safety.

Key Features of Modern Systems

- Robotic arms for precise application

- Programmable controls for repeatable processes

- Advanced filtration and ventilation for environmental compliance

- Integration with production lines for seamless operation

- Real-time monitoring and analytics for quality assurance

Why Choose Automatic Spray Booth Systems?

Enhanced Efficiency and Productivity

Automated spray booths significantly increase throughput by minimizing manual intervention and reducing cycle times. Robots can operate continuously, handle repetitive tasks, and maintain a high level of accuracy, which is crucial for industries with large-scale production needs.

Consistent Quality and Reduced Waste

Automation ensures uniform application of coatings, reducing the likelihood of defects, rework, or product rejection. Precise control over spray patterns and material usage minimizes overspray and resource wastage, leading to cost savings and environmental benefits.

Improved Safety and Compliance

By automating hazardous tasks, companies protect workers from exposure to toxic fumes and chemicals. Modern booths are designed to meet stringent safety and environmental regulations, further reducing operational risks.

Top Industries Benefiting from Automatic Spray Booth Systems

Automotive Industry

Applications

- Painting car bodies, parts, and accessories

- Applying protective coatings to chassis and underbodies

- Custom finishes for aftermarket and specialty vehicles

Advantages

The automotive sector was among the earliest adopters of automated spray booths. High production volumes, strict quality standards, and the need for rapid color changes make automation indispensable. Robotic systems ensure flawless finishes, minimize paint usage, and allow for flexible manufacturing lines that can adapt to different vehicle models and customizations.

Aerospace Industry

Applications

- Coating aircraft fuselages, wings, and components

- Applying anti-corrosion and fire-retardant finishes

- Painting interior panels and seating structures

Advantages

Aerospace manufacturing demands precision and reliability. Automated spray booths deliver the uniform coverage and film thickness required for safety-critical parts. They also help meet rigorous regulatory standards while reducing turnaround times for both new builds and maintenance operations.

Electronics Industry

Applications

- Applying conformal coatings to circuit boards

- Encapsulating sensitive components

- Coating enclosures for consumer electronics

Advantages

The electronics industry benefits from the precision and repeatability of automated spray booths, which are essential for protecting delicate circuitry from moisture, dust, and contaminants. Automation ensures that coatings are applied evenly without damaging sensitive parts, supporting high-volume and high-mix production environments.

Furniture and Woodworking

Applications

- Finishing wooden furniture, cabinets, and panels

- Applying stains, varnishes, and lacquers

- Coating metal and composite furniture

Advantages

Automated spray booths provide a dust-free environment and consistent application, resulting in superior surface finishes. They also reduce labor costs and material waste, making them ideal for both large-scale manufacturers and custom woodworking shops seeking to improve quality and efficiency.

Industrial Manufacturing

Applications

- Coating machinery, tools, and equipment

- Applying protective and decorative finishes to metal, plastic, and composite parts

Advantages

Manufacturers of industrial equipment and components use automated spray booths to achieve durable, high-quality finishes that withstand harsh operating conditions. Automation supports high-volume production and allows for rapid changeovers between product types and coatings.

Commercial Vehicles and Semis

Applications

- Painting trucks, buses, trailers, and specialty vehicles

- Applying corrosion-resistant and weatherproof coatings

Advantages

The large size and complex shapes of commercial vehicles make manual coating challenging. Automated spray booths, often equipped with multi-axis robots, ensure complete coverage and uniform thickness, improving durability and appearance while reducing labor costs.

Appliance Manufacturing

Applications

- Coating refrigerators, ovens, washing machines, and HVAC units

- Applying powder coatings and enamels for durability and aesthetics

Advantages

In appliance manufacturing, automated spray booths provide the speed and consistency needed for mass production. They also help manufacturers comply with environmental regulations by minimizing emissions and waste.

Metalworking and Plastics

Applications

- Coating metal parts, tools, and assemblies

- Applying finishes to plastic components such as bumpers and enclosures

Advantages

Automated booths deliver consistent finishes on complex shapes and surfaces, reducing the risk of defects and improving product longevity. They also enable rapid adaptation to different part geometries and coating materials.

Food and Beverage Industry

Applications

- Applying edible coatings, flavorings, and colorants to food products

- Coating food processing equipment for hygiene and safety

Advantages

Spray booths in the food industry must meet strict hygiene standards. Automation ensures precise application of coatings while minimizing contamination risks. These systems are also used to apply sanitary coatings to equipment, enhancing food safety and compliance.

How to Select the Right Automatic Spray Booth System

Assessing Production Needs

- Volume and Repetition: High-volume, repetitive processes benefit most from automation.

- Product Dimensions: Booth size and configuration must accommodate the largest items.

- Finish Requirements: Consider the type and quality of finish needed.

Choosing the Right Configuration

- Synchronous Booths: Ideal for fast, high-volume production lines.

- Non-Synchronous Booths: Offer flexibility for varied product types.

- Single Station Booths: Cost-effective for smaller operations or specialized tasks.

- Continuous Booths: Best for extremely high throughput and minimal downtime.

Integration with Existing Operations

- Connectivity: Modern systems can integrate with cloud networks for real-time monitoring.

- Analytics: Advanced diagnostics help optimize performance and maintenance.

- Safety Features: Ensure compliance with local regulations and industry standards.

Future Trends in Automatic Spray Booth Systems

Advanced Robotics and AI

Robotic arms are becoming more sophisticated, with AI-driven programming enabling adaptive spray paths and self-optimization based on product geometry and coating requirements.

Sustainable Practices

Manufacturers are investing in systems that reduce volatile organic compound (VOC) emissions, recycle overspray, and use water-based or powder coatings to minimize environmental impact.

Digitalization and Industry 4.0

Spray booths are increasingly integrated into smart factories, with data analytics, remote monitoring, and predictive maintenance becoming standard features.

Frequently Asked Questions

1. What are the main benefits of using automatic spray booth systems over manual systems?

Automatic spray booths offer consistent quality, higher efficiency, reduced labor costs, improved safety, and lower material waste compared to manual systems.

2. Can automatic spray booths handle different types of coatings and products?

Yes, modern systems are highly adaptable and can be programmed for various coatings, including paints, powders, lacquers, and even edible coatings for food products.

3. Are automatic spray booths suitable for small businesses?

While the initial investment is higher, single station or semi-automated booths are available for smaller operations, offering scalability as business needs grow.

4. How do automated spray booths improve workplace safety?

By automating hazardous tasks, these systems reduce worker exposure to toxic fumes and chemicals, lowering health risks and ensuring regulatory compliance.

5. What maintenance is required for automatic spray booth systems?

Regular maintenance includes cleaning filters, checking robotic components, calibrating sensors, and updating software to ensure optimal performance and longevity.

Citations:

[1] https://www.spraysystems.com/industries/

[2] https://www.spraysystems.com/how-automated-spray-booth-systems-can-save-you-time-and-money/

[3] https://www.ramseierkoatings.com/which-are-the-top-industries-benefiting-from-automatic-spray-booth-systems.html

[4] https://automatedsolutions.com.au/automated-spray-booth/

[5] https://www.codinter.com/en/spray-booths-a-complete-guide/

[6] https://paintfinishingequipment.com/spray-booths/

[7] https://www.businesswire.com/news/home/20170201005674/en/Top-5-Vendors-in-the-Global-Robotic-Paint-Booth-Market-from-2017-to-2021-Technavio

[8] https://www.gemapowdercoating.com/en/products/automatic-booth-systems

[9] https://www.futuremarketinsights.com/reports/spray-booth-ventilation-system-market

[10] https://ensun.io/search/paint-booth

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.