Content Menu

● Understanding Powder Coating Systems

>> What Is a Powder Coating System?

>> Key Components of a Swinger Powder Coating System

● Factors to Consider When Choosing a Swinger Powder Coating System

>> Production Volume and Throughput

>> Part Size, Shape, and Material

>> Powder Type Compatibility

● Technical Features to Look for in Swinger Powder Coating Systems

>> Spray Booth Design and Gun Arrangement

>> Curing Oven Types

>> Conveyor System and Workpiece Handling

>> Powder Recovery and Environmental Considerations

● Customization and Automation Options

>> Automation Benefits

>> Tailoring to Industry Requirements

● Installation, Maintenance, and Operational Support

● Case Examples of Swinger Powder Coating Applications

● Conclusion

● Related Questions and Answers

Powder coating has become a preferred finishing process for many industries due to its durability, environmental friendliness, and cost-effectiveness. When setting up a production line that uses powder coating, selecting the appropriate swinger powder coating system is pivotal to ensuring efficiency, quality, and scalability. This article will guide you through the essential factors and features to consider when choosing the right system for your production needs.

Understanding Powder Coating Systems

What Is a Powder Coating System?

A powder coating system utilizes electrostatically charged powder particles applied to a workpiece and then cured through baking to form a durable, smooth finish. Such systems are often integrated into production lines that require consistent surface finishing.

Key Components of a Swinger Powder Coating System

To select the best system, it is essential to understand its core components:

- Pretreatment Station: This includes cleaning, degreasing, and sometimes phosphating to prepare the surface for optimal adhesion.

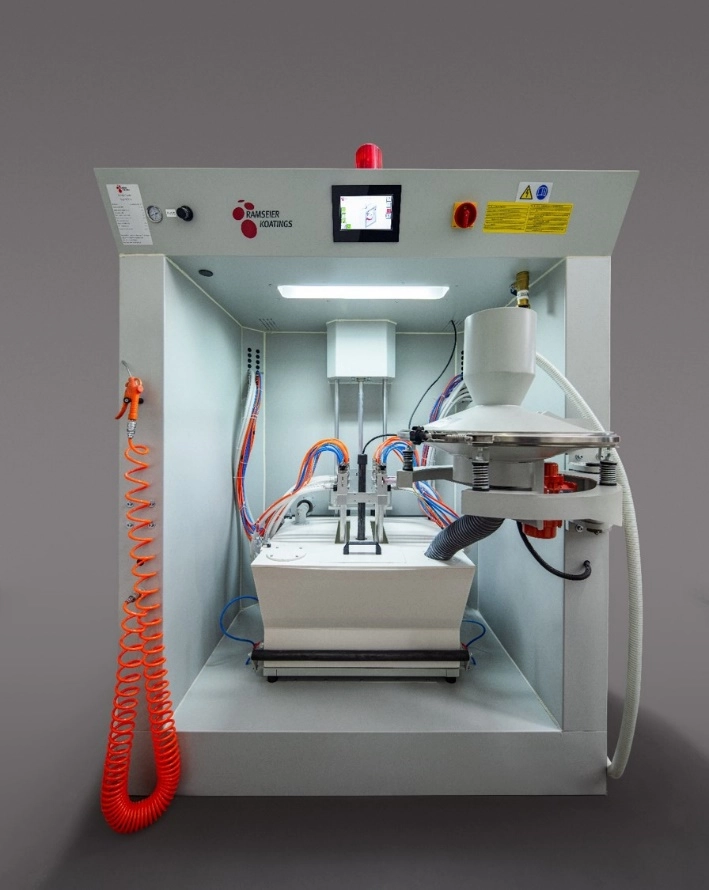

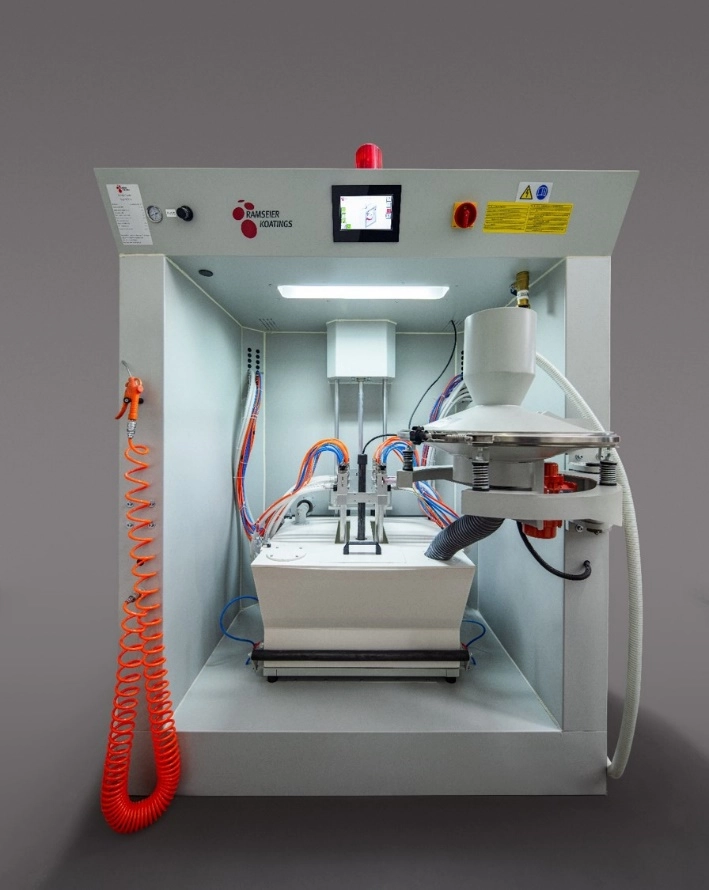

- Powder Application Booth: Equipped with electrostatic spray guns that evenly apply the powder.

- Curing Oven: Cures the powder, usually by baking at controlled temperatures, causing it to melt and chemically bond or physically harden.

- Conveyor and Handling System: Moves parts efficiently through each stage and provides grounding for electrostatic application.

- Powder Recovery Unit: Reclaims overspray powder to reduce waste.

- Control System: Manages operational parameters to maintain consistent quality[1].

In swinger powder coating systems, specifically, the "swinger" mechanism helps move parts through the spray area correctly, often used for irregular shapes or complex geometries.

Factors to Consider When Choosing a Swinger Powder Coating System

Production Volume and Throughput

The speed and volume of your production line will significantly influence system selection:

- Small Batch Production: Manual or semi-automatic systems with flexible swinger arms allow for customization and smaller throughput.

- High-Volume Production: Fully automated swinger lines with multiple spray guns and fast conveyor systems provide high efficiency, coating up to 1,500 parts per hour or more depending on part size and complexity[1].

Part Size, Shape, and Material

The shape and size range of your workpieces impact the swinger system design.

- Large or bulky parts require robust swinger mechanisms capable of holding and rotating heavy loads.

- Complex shapes need multiple spray guns arranged to reach all surfaces.

- Material heat sensitivity dictates oven type and temperature settings; for example, thermosetting powders typically cure at 160-200°C, but thermoplastic powders may require higher temperatures or longer curing times[1].

Powder Type Compatibility

There are two major powder categories to consider:

- Thermosetting Powders: Cure chemically during baking and form hard, resistant coatings. Suitable for both indoor and outdoor applications with excellent adhesion and weather resistance.

- Thermoplastic Powders: Melt and harden but do not chemically change, allowing reshaping and recycling. Often used for applications requiring flexibility or chemical resistance[1].

Ensure your swinger system supports the curing parameters and recovery compatible with your chosen powder type.

Technical Features to Look for in Swinger Powder Coating Systems

Spray Booth Design and Gun Arrangement

Proper booth design is crucial to:

- Contain overspray and facilitate powder recovery.

- Incorporate fixed and movable swingers for thorough coverage.

- Optimize electrostatic spray gun position and voltage (typically 40 to 80 kV) to maximize adherence without safety risks[1].

Curing Oven Types

Various curing oven technologies include:

- Convection ovens: Use hot air circulation for even heating, suited for most metal substrates.

- Infrared ovens: Provide quicker curing, beneficial for certain powders or production speeds.

- UV-curable powder coatings: Require specialized UV ovens for curing at lower temperatures, enabling coating of heat-sensitive materials such as plastics or wood[1].

Choose an oven that matches your production speed requirements and substrate tolerance.

Conveyor System and Workpiece Handling

The conveyor system must:

- Keep workpieces grounded for electrostatic application.

- Support swinger arms with sufficient load capacity.

- Move parts at speeds that align with booth, oven, and recovery system capacity to avoid bottlenecks.

- Offer customization in path layout, speed, and density to fit factory space and workflow[1].

Powder Recovery and Environmental Considerations

An efficient recovery system minimizes waste, improves cost-efficiency, and maintains environmental compliance:

- Use combined cyclone and bag filter systems to capture fine powders.

- Ensure the design aligns with your powder type and volume.

- Confirm the system processes recovered powder to maintain coating quality[1].

Customization and Automation Options

Automation Benefits

Automated swinger powder coating lines include features like:

- Computer-controlled oscillating and fixed spray guns.

- Programmable Logic Controllers (PLCs) for line speed and curing management.

- Robotic handling for precision and repeatability.

- Touch-up booths for re-spraying missed spots, improving final quality[1].

Automation optimizes throughput and reduces human error but requires a higher initial investment.

Tailoring to Industry Requirements

Depending on the industry served—whether automotive, appliances, furniture, or infrastructure—swinger lines can be customized for:

- Specific powder types (epoxy, polyurethane, polyester).

- Environmental controls for volatile organic compound reduction.

- Compliance with specific standards and certifications.

Customization ensures your system fits your product demands precisely, maximizing ROI[1].

Installation, Maintenance, and Operational Support

- Choose suppliers that offer comprehensive installation and training services.

- Prioritize systems with accessible components to facilitate maintenance.

- Ensure availability of spare parts and technical support to minimize downtime.

- Implement quality control monitoring systems integrated within the control system for process optimization[1].

Case Examples of Swinger Powder Coating Applications

Common applications include:

- Household appliances like washing machines and refrigerators, requiring smooth, durable finishes.

- Automotive parts, benefiting from corrosion resistance and aesthetic appeal.

- Outdoor furniture and structural components that need weather-resistant coatings[1].

These examples underline the significance of choosing a versatile, high-precision swinger system aligned with product specifications.

Conclusion

Selecting the right swinger powder coating system for your production line requires a comprehensive assessment of production volumes, part characteristics, powder types, and operational requirements. By focusing on component quality, system automation, and customization, manufacturers can optimize their coating process to achieve efficiency, durability, and superior product finish.

Related Questions and Answers

1. What types of powders are best suited for swinger systems?

Thermosetting powders are most commonly used due to their durable finish, but thermoplastic powders can be used for applications requiring flexibility and remelting.

2. How does part size affect the choice of swinger powder coating system?

Larger or irregularly shaped parts require robust swingers capable of handling weight and ensuring full surface coverage with multiple spray guns.

3. Can swinger systems handle both manual and automated operations?

Yes, swinger systems come in manual, semi-automatic, and fully automatic configurations depending on production demands.

4. What curing methods are compatible with swinger powder coating systems?

Mostly convection ovens are used, though infrared and UV curing ovens are options depending on powder type and substrate.

5. How important is powder recovery in swinger systems?

Very important—efficient recovery lowers waste, reduces costs, and supports sustainable operations.

[1] https://tifuls.com/powder-coating-line/

[2] https://huggingface.co/facebook/xm_transformer_unity_hk-en/commit/e37fd5ab9c6faf7a9547972cf6dace1c144c49c8.diff?file=en_zh_spm.dict

[3] https://finishingandcoating.com/index.php/powder-coat/1986-line-balancing-synchronization-in-powder-coating-workstation-a-case-study

[4] https://www.scribd.com/document/666776779/%E5%A6%82%E9%B1%BC%E5%BE%97%E6%B0%B4%E8%AE%B0%E5%8D%95%E8%AF%8D-%E4%B8%93%E4%B8%9A%E5%85%AB%E7%BA%A7%E8%AF%8D%E6%B1%87%E8%AF%AD%E5%A2%83%E8%AE%B0%E5%BF%86-%E8%8C%85%E9%A3%8E%E5%8D%8E-Z-Library

[5] https://surplusrecord.com/machinery-equipment/paint-and-powder-systems/

[6] https://www.cs.cmu.edu/afs/cs.cmu.edu/project/cmt-40/Nice/Transfer/Chinese/xferlexicon

[7] https://www.tmcoinc.com/capability/finishing/conveyor-driven-powder-coat-line/

[8] https://www.scribd.com/document/10317685/%E5%A4%A7%E5%AD%A6%E7%A7%91%E6%8A%80%E8%8B%B1%E8%AF%AD

[9] https://hannapowdercoating.en.made-in-china.com/product/IElpvVhJOoWa/China-Powder-Coating-Machine-for-Sale-Best-Powder-Coating-System-Powder-Coating-Production-Line.html

[10] https://huggingface.co/openbmb/cpm-bee-1b/commit/bd72a61dd7a59086ed7456f1dfcaa995c8ec58a3.diff

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.