Content Menu

● Understanding Compressed Air Systems

>> What Is a Compressed Air System?

>> Common Uses in Powder Conveying

● Limitations of Compressed Air Systems in Powder Supply

>> Energy Inefficiency and Pressure Loss

>> Inadequate for Certain Powder Handling Needs

>> Safety Concerns with Reactive Powders

● What Distinguishes Our Powder Supply System?

>> Closed-Loop Circulation with Gas Compression

>> Advantages of Using Inert or Pure Gas Media

>> Specialized Powder Crushing and Classification

>> Gas Compensation and Monitoring

● Operational Efficiency and Energy Use

>> Optimized Gas Circulation

>> Reduced Pressure Drops and Leakages

● Application Versatility

>> Suitable for High-Purity and Sensitive Powders

>> Safe Handling of Reactive Materials

>> Environmental and Regulatory Compliance

● Summary of Key Differences

● Conclusion

● Related Questions and Answers

● Citations:

In industrial and manufacturing environments, the efficient and safe handling of powders is critical. Traditional compressed air systems have long been used for powder conveying and supply, but recent innovations in powder supply technology have introduced systems that offer distinct advantages over conventional compressed air methods. This article explores what differentiates our powder supply system from standard compressed air systems, focusing on design, efficiency, safety, and application versatility.

Understanding Compressed Air Systems

What Is a Compressed Air System?

A compressed air system is a motor-driven mechanical device designed to compress and pressurize air, which is then used to power tools, operate machinery, or convey materials within a facility. The air is compressed into a smaller volume, stored under pressure in tanks, dried to reduce humidity, and distributed through a network of pipes and valves to various points of use[5][7].

Common Uses in Powder Conveying

Compressed air systems are often employed in pneumatic conveying of powders, where pressurized air moves powder through pipelines. These systems rely on the energy stored in compressed air to transport materials, balancing supply and demand to maintain operational efficiency[2]. There are two main types of compressed air distribution systems: centralized, where large compressors feed the entire facility, and decentralized, where smaller compressors serve localized needs[3].

Limitations of Compressed Air Systems in Powder Supply

Energy Inefficiency and Pressure Loss

Compressed air systems consume significant energy to compress air and maintain pressure. Energy losses occur not only during compression but also due to leaks and pressure drops in piping. Improperly sized or laid-out piping can exacerbate these inefficiencies, leading to higher operational costs and inconsistent powder delivery[2][7].

Inadequate for Certain Powder Handling Needs

Compressed air systems are generally designed for high pressure and relatively low flow rates. However, for lean phase conveying of powders, blowers rather than compressors are often more suitable due to their ability to deliver high flow at low pressure. Moreover, vacuum pumps, which generate negative pressure, are sometimes preferred for recirculating powders but are limited by low flow capacity and cannot replace compressed air pumps in dense phase conveying[4].

Safety Concerns with Reactive Powders

Handling powders that are flammable, explosive, or prone to oxidation poses risks in compressed air systems because the air used is typically ambient air containing oxygen and moisture. This can lead to contamination, oxidation, or even combustion hazards during powder processing[6].

What Distinguishes Our Powder Supply System?

Our powder supply system is designed to overcome the limitations of traditional compressed air systems by integrating advanced technology and process controls that enhance efficiency, safety, and adaptability.

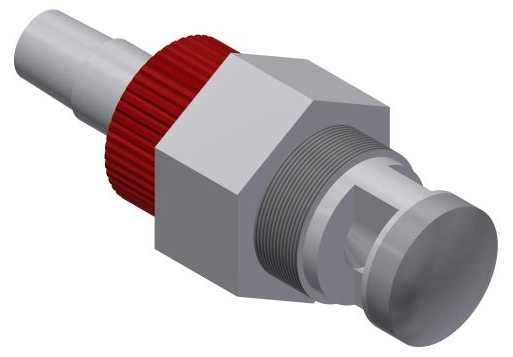

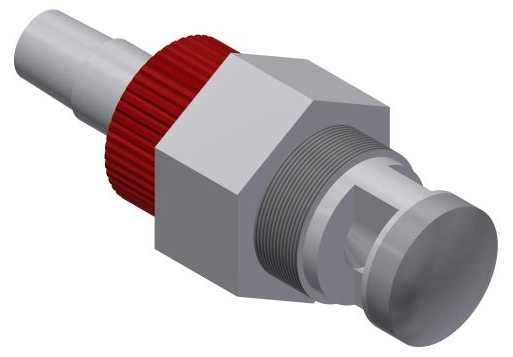

Closed-Loop Circulation with Gas Compression

Unlike conventional systems that use ambient compressed air, our system employs a closed-loop circulation of gas media through a gas compressor. This compressor supplies compressed inert gases such as nitrogen or argon, or purified air, to the powder processing equipment. The gas circulates continuously between the powder crushing and collection units, maintaining a sealed environment that prevents contamination and dust escape[6].

Advantages of Using Inert or Pure Gas Media

- Prevention of Oxidation and Contamination: By using inert gases, the system avoids introducing oxygen and moisture that can oxidize sensitive powders or degrade product quality.

- Enhanced Safety for Flammable or Explosive Powders: The absence of oxygen in the gas medium significantly reduces the risk of combustion or explosion during powder handling.

- Environmental Protection: The closed system prevents powder dust from escaping into the atmosphere, reducing environmental pollution and workplace hazards[6].

Specialized Powder Crushing and Classification

Our system includes a powder crushing and classification unit equipped with a sealed grinding chamber and a classification wheel. This setup allows precise control over powder particle size within a contained environment. The crushing chamber is connected to the gas compressor via a flow distribution chamber and supersonic nozzles, ensuring efficient powder processing and transport[6].

Gas Compensation and Monitoring

To maintain optimal operating conditions, the system features a gas compensation pipeline and tank equipped with oxygen concentration sensors. This allows real-time monitoring and adjustment of the gas composition inside the system, ensuring consistent inert conditions and process stability[6].

Operational Efficiency and Energy Use

Optimized Gas Circulation

Our powder supply system's closed-loop design recirculates the gas medium, drastically reducing the volume of gas that must be compressed continuously. This contrasts with compressed air systems that consume air continuously from the atmosphere, leading to higher energy demands[6].

Reduced Pressure Drops and Leakages

By maintaining a sealed circuit and using specialized piping and connections, the system minimizes pressure drops and leakage points, which are common in traditional compressed air networks. This results in more consistent powder flow and lower energy consumption[6][7].

Application Versatility

Suitable for High-Purity and Sensitive Powders

The system is ideal for industries requiring ultra-high purity powders, such as pharmaceuticals, food processing, and advanced materials manufacturing. The closed environment and inert gas use prevent contamination and preserve material integrity[6].

Safe Handling of Reactive Materials

For chemical, metallurgical, and powder metallurgy industries dealing with flammable, explosive, or oxidation-sensitive powders, our system provides a safer alternative to compressed air systems by eliminating oxygen exposure and reducing explosion risks[6].

Environmental and Regulatory Compliance

Because the system prevents dust emissions and controls gas composition, it helps facilities meet stringent environmental regulations and workplace safety standards, reducing liability and improving operational sustainability[6].

Summary of Key Differences

| Feature | Our Powder Supply System | Traditional Compressed Air System |

| Gas Medium | Inert gas (N2, Ar) or purified air in closed loop | Ambient compressed air from atmosphere |

| System Design | Closed-loop circulation with gas compressor | Open system with continuous air intake |

| Safety | Reduced explosion/oxidation risk via inert gas | Higher risk due to oxygen and moisture in air |

| Contamination Control | Sealed environment preventing dust ingress/egress | Possible contamination from ambient air |

| Energy Efficiency | Recirculated gas reduces compression load | Continuous compression of atmospheric air |

| Application Suitability | High-purity, flammable, oxidation-sensitive powders | General powder conveying |

Conclusion

Our powder supply system sets itself apart from traditional compressed air systems through its innovative closed-loop design using inert or purified gases, enhanced safety features, contamination control, and energy efficiency. These advantages make it particularly suited for industries handling sensitive, reactive, or high-purity powders, providing both operational and environmental benefits that conventional compressed air systems cannot match.

---

Related Questions and Answers

Q1: Why is inert gas used instead of ambient air in some powder supply systems?

A1: Inert gases prevent oxidation, contamination, and reduce the risk of combustion or explosion when handling sensitive or flammable powders.

Q2: How does a closed-loop powder supply system improve energy efficiency?

A2: It recirculates the gas medium, reducing the need to continuously compress fresh air, thereby lowering energy consumption.

Q3: Can compressed air systems handle all types of powders safely?

A3: No, powders that are flammable, explosive, or oxidation-sensitive require specialized systems like inert gas closed-loop systems for safe handling.

Q4: What are the main components of a traditional compressed air system?

A4: They include air compressors, dryers, storage tanks, distribution piping, valves, and end-use equipment.

Q5: How does the powder crushing unit in our system maintain powder quality?

A5: It uses a sealed crushing chamber with a classification wheel and controlled gas flow to finely grind and classify powders without contamination.

---

Citations:

[1] https://www.eng-tips.com/threads/powder-conveying-help-vacuum-pump-vs-air-blower-vs-air-compressor-vs-compressed-air-pump.511684/

[2] https://www.airbestpractices.com/system-assessments/pipingstorage/matching-supply-and-demand-compressed-air-system

[3] https://kaishanusa.com/blog-centralized-vs-decentralized-compressed-air-distribution-systems/

[4] https://www.reddit.com/r/ChemicalEngineering/comments/16baacx/vacuum_pump_vs_compressed_air_pump_vs_air/

[5] https://jhfoster.com/automation-blogs/what-are-the-parts-of-a-compressed-air-system-jhfoster/

[6] https://patents.google.com/patent/CN108452917B/zh

[7] https://fluidairedynamics.com/blogs/articles/compressed-air-101-the-basics

[8] https://www.cnblogs.com/luohenyueji/p/16990846.html

---

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.