Content Menu

● Introduction to Spray Booths

● Manual Spray Booths

● Automated Spray Booths

● Key Differences Between Manual and Automated Systems

>> Precision and Customization

>> Efficiency and Productivity

>> Safety and Environmental Impact

>> Cost and Investment

● Choosing Between Manual and Automated Spray Booths

● Future Developments and Trends

● Conclusion

● Frequently Asked Questions

● Citations:

In the realm of industrial painting and coating, spray booths are essential tools for ensuring quality, safety, and efficiency. These booths can be broadly categorized into manual and automated systems, each with its unique advantages and applications. Understanding the differences between these systems is crucial for businesses looking to optimize their operations.

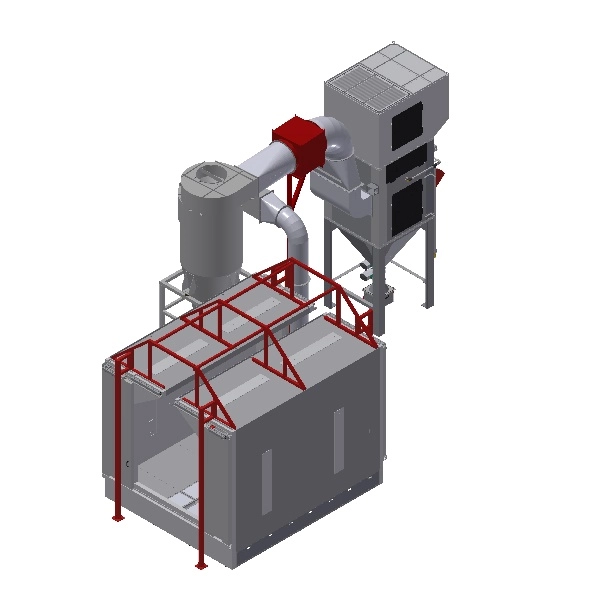

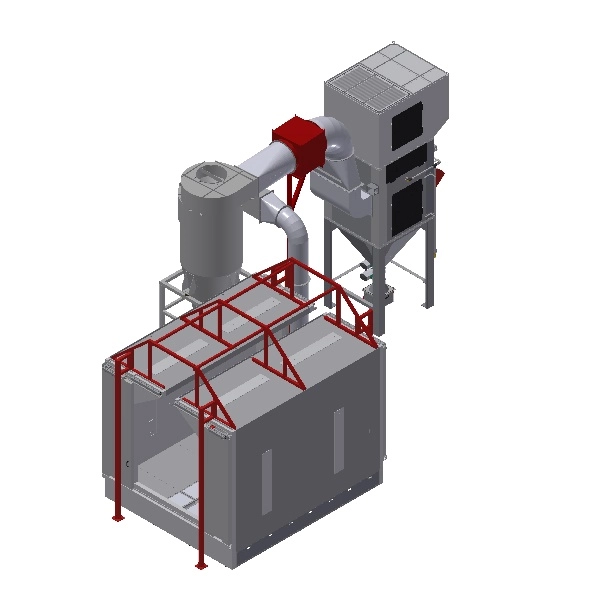

Introduction to Spray Booths

Spray booths are enclosed environments designed to contain the spraying process, protecting workers from harmful fumes and particles while maintaining a clean workspace. They are equipped with ventilation systems that draw in clean air and exhaust contaminated air, ensuring a safe and controlled environment for painting. This setup not only enhances safety but also improves the quality of the finish by minimizing dust and debris.

Manual Spray Booths

Manual spray booths are ideal for low-volume, high-customization projects where precision and detail are paramount. These booths allow skilled operators to meticulously apply coatings, making them perfect for custom jobs and small batches. The flexibility of manual booths enables intricate detailing, which can be challenging for automated systems to replicate. However, manual spray booths require skilled labor, which can increase labor costs and time per unit.

The primary benefit of manual spray booths lies in their adaptability. For businesses handling diverse products requiring varied finishes, manual booths provide the perfect environment for achieving high-quality, bespoke results. Despite the labor-intensive nature of manual spraying, which can lead to inconsistencies in application, manual booths remain essential for projects that demand a human touch.

Automated Spray Booths

Automated spray booths excel in high-volume production settings, offering unparalleled consistency and efficiency. These systems ensure uniform application, reduce waste, and improve throughput. While the initial investment in automated booths is higher, the return on investment is significant due to reduced labor costs and increased production speed.

Automated booths utilize advanced technology to control various aspects of the painting process, from airflow and temperature to paint application and curing times. This precision ensures consistent and high-quality finishes, making them ideal for large-scale operations. However, the complexity of automated systems necessitates regular maintenance and skilled technicians to manage potential technical issues.

Key Differences Between Manual and Automated Systems

Precision and Customization

- Manual Systems: Offer greater flexibility and customization, allowing for intricate detailing and precision that may be difficult to achieve with automated systems.

- Automated Systems: Provide uniform coverage and consistency, which is crucial for high-volume production where precision is less about customization and more about uniformity.

Efficiency and Productivity

- Manual Systems: Require more time and labor, which can lead to higher costs and lower productivity compared to automated systems.

- Automated Systems: Significantly enhance efficiency and productivity by reducing manual labor and increasing production speed.

Safety and Environmental Impact

- Manual Systems: While they offer a controlled environment, manual booths still expose workers to potential hazards if not properly managed.

- Automated Systems: Minimize human exposure to hazardous substances and reduce environmental impact by optimizing material usage and reducing waste.

Cost and Investment

- Manual Systems: Generally have lower initial costs but may incur higher labor costs over time.

- Automated Systems: Require a higher initial investment but offer long-term savings through reduced labor costs and increased efficiency.

Choosing Between Manual and Automated Spray Booths

The choice between manual and automated spray booths depends on the specific needs of the business. For companies focusing on high-volume production with consistent requirements, automated booths are the better choice. However, for businesses that prioritize customization and precision, manual booths remain the ideal option.

Future Developments and Trends

As technology continues to evolve, we can expect to see advancements in both manual and automated spray booths. Automated systems may become more adaptable and customizable, potentially bridging the gap between precision and efficiency. Meanwhile, manual booths may incorporate more technology to enhance precision and reduce labor costs.

Conclusion

In conclusion, manual and automated spray booths serve distinct purposes in industrial painting. While manual booths excel in customization and precision, automated systems offer efficiency and consistency. Understanding these differences is crucial for businesses looking to optimize their operations and achieve high-quality finishes.

Frequently Asked Questions

1. What are the primary advantages of manual spray booths?

- Manual spray booths offer precision, customization, and flexibility, making them ideal for low-volume, high-customization projects.

2. What are the benefits of automated spray booths?

- Automated spray booths provide consistency, efficiency, and reduced labor costs, making them suitable for high-volume production.

3. How do spray booths enhance safety?

- Spray booths protect workers from harmful fumes and particles by providing a controlled environment with proper ventilation and safety features.

4. What factors should be considered when choosing between manual and automated spray booths?

- Considerations include production volume, customization needs, labor costs, and the type of finish required.

5. Can automated spray booths be customized for specific applications?

- Yes, automated spray booths can be programmed and customized to meet specific requirements, including different paint types and application methods.

---

Citations:

[1] https://www.pbmetalfinishingsystems.com/news/comparing-manual-vs-automated-spray-equipment-for-industrial-applications

[2] https://www.codinter.com/en/spray-booths-a-complete-guide/

[3] https://synergyspray.com/benefits-of-automatic-spray-systems/

[4] https://pfsspraybooths.com/advantages-of-using-automated-spray-booths-in-your-operation

[5] https://www.hppneumatics.com/spray-booth-benefits/

[6] https://www.ceflafinishing.com/en/products/manual-spray-booths-for-finishing

[7] https://www.duboisequipment.com/benefits-of-automated-spray-coating-systems/

[8] https://roboticpaint.com/how-to-select-a-suitable-paint-booth/

[9] https://www.powderspraymachine.com/adding-manual-conveyor-lines-to-paint-booths/

[10] https://arnoldmachine.com/resources/automated-spray-systems-key-to-increased-efficiency/

[11] https://www.colourspray.com/manual-powder-coating-spray-booth.html

[12] https://watertransferprinting.com/equipment/automated-spray-systems/

[13] https://www.spraysystems.com/essential-design-elements-of-a-spray-booth-coatings-involved-in-the-finishing-process/

[14] https://www.iqsdirectory.com/articles/paint-finishing-equipment/paint-spray-booths.html

[15] https://arnoldmachine.com/resources/benefits-of-automated-spray-coating-systems/

[16] https://www.nordson.com/en/products/industrial-coating-systems-products/manual-powder-coating-booth

[17] https://arnoldmachine.com/expertise/coating-systems/

[18] https://www.colo-group.com/closed-powder-coating-booth-15241932163728183.html

[19] https://bete.com/product/custom-spray-systems/

[20] https://www.spraysystems.com/how-automated-spray-booth-systems-can-save-you-time-and-money/

.

.