Content Menu

● Introduction

● What is Sames Powder Coating Equipment?

>> Key Features of Sames Powder Coating Equipment

● Why Choose OEM Services for Sames Powder Coating Equipment?

>> Benefits of OEM Partnerships

● Applications of Sames Powder Coating Equipment

>> Industrial and Commercial Uses

>> Manual vs. Automatic Systems

● Technical Insights into Sames Powder Coating Equipment

>> Fluidization and Powder Transfer

>> Ergonomics and User Experience

>> Maintenance and Durability

● Our OEM Manufacturing Capabilities

>> Comprehensive Production and Design Services

>> Quality Control and Compliance

● Conclusion

● Frequently Asked Questions (FAQs)

Introduction

In the fast-evolving world of industrial coatings, powder coating stands out for its durability, environmental benefits, and superior finish quality. As a leading Chinese manufacturer, supplier, and OEM service provider for international powder coating equipment brands, we specialize in delivering high-quality, customized solutions centered around the renowned keyword: sames powder coating equipment. This article explores the advantages, technology, and OEM partnership opportunities with Sames powder coating equipment, helping global brands and wholesalers elevate their production capabilities.

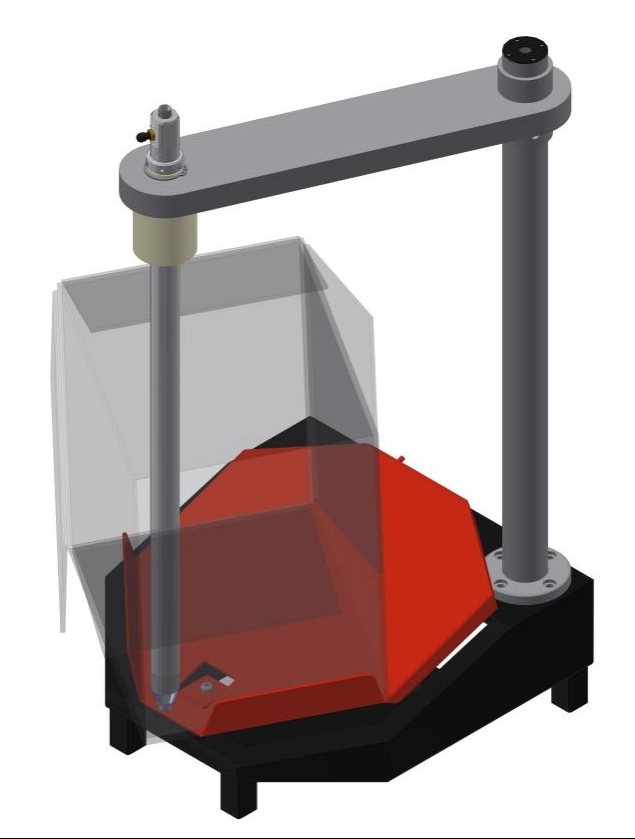

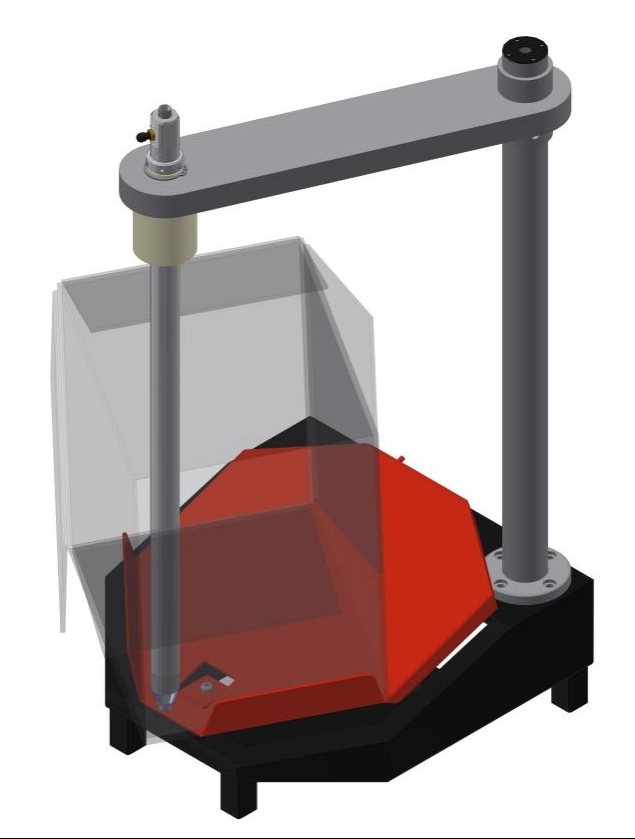

What is Sames Powder Coating Equipment?

Sames is a globally recognized brand known for its advanced powder coating solutions that have been enhancing productivity since 1960. Their product range includes manual and automatic guns, pumps, controllers, and complete finishing application systems designed for precision and efficiency[1][5]. The sames powder coating equipment line is celebrated for delivering smooth, consistent, and durable coatings across various industrial applications.

Key Features of Sames Powder Coating Equipment

- High fluidization technology for smooth powder flow

- Efficient powder transfer systems reducing waste

- Ergonomic designs for ease of use and operator comfort

- Quick color change capabilities to minimize downtime

- Robust components ensuring long service life and low maintenance[1][2]

Why Choose OEM Services for Sames Powder Coating Equipment?

Benefits of OEM Partnerships

As a professional OEM manufacturer and supplier based in China, we provide tailor-made manufacturing and design services for sames powder coating equipment to meet the specific needs of foreign brands, wholesalers, and producers. The benefits include:

- Cost Efficiency: Lower production costs without compromising quality

- Customization: Adapt equipment design to unique production requirements

- Scalability: Easily scale production volumes according to market demand

- Quality Assurance: Strict quality control aligned with international standards

- After-Sales Support: Comprehensive technical support and spare parts availability

OEM cooperation enables brands to leverage our manufacturing expertise and advanced technology while maintaining their brand identity and market presence.

Applications of Sames Powder Coating Equipment

Industrial and Commercial Uses

The versatility of sames powder coating equipment makes it suitable for a wide range of industries, including automotive, furniture, appliances, and construction materials. Powder coating offers superior resistance to corrosion, chemicals, and weathering, making it ideal for both indoor and outdoor applications[8].

Manual vs. Automatic Systems

- Manual Systems: Ideal for small to medium-sized batches, offering flexibility and precision. Sames manual guns like the Inogun M paired with Inobox control modules provide user-friendly interfaces and ergonomic operation[2].

- Automatic Systems: Designed for high-volume production lines, these systems include robotic guns and automated bells that ensure consistent coating quality and faster throughput[1][7].

Technical Insights into Sames Powder Coating Equipment

Fluidization and Powder Transfer

Sames equipment employs advanced fluidization technology to maintain powder flow consistency, which is critical for achieving uniform coating thickness and finish quality. Efficient powder transfer mechanisms reduce overspray and material waste, enhancing cost-effectiveness[1][5].

Ergonomics and User Experience

The design of sames powder coating equipment focuses on operator comfort and ease of use. Features like lightweight guns, balanced handling, and intuitive controls reduce operator fatigue and improve productivity[2].

Maintenance and Durability

Durability is a hallmark of Sames equipment, with stainless steel hoppers and wear-resistant components designed for industrial environments. Preventative maintenance is facilitated by monitoring systems that track wear parts, ensuring longevity and minimizing downtime[7].

Our OEM Manufacturing Capabilities

Comprehensive Production and Design Services

We offer end-to-end OEM services for sames powder coating equipment, including:

- Custom design adaptations based on client specifications

- Precision manufacturing with advanced CNC and assembly lines

- Quality testing aligned with international standards

- Packaging and logistics support for global shipping

Quality Control and Compliance

Our factory adheres to strict quality management systems (ISO 9001, ISO 14001) ensuring every unit meets or exceeds client expectations. We collaborate closely with clients to maintain brand consistency and product reliability.

Conclusion

Partnering with a reliable OEM manufacturer for sames powder coating equipment empowers international brands and wholesalers to deliver superior powder coating solutions efficiently and cost-effectively. With decades of industry experience, cutting-edge technology, and a commitment to quality, our factory stands as a trusted partner in the global powder coating equipment market.

Frequently Asked Questions (FAQs)

Q1: What types of powder coating equipment does Sames offer?

A1: Sames offers a wide range including manual and automatic guns, pumps, controllers, and complete finishing application systems[1][2].

Q2: Can OEM services customize Sames powder coating equipment?

A2: Yes, OEM services provide customization to meet specific production and design requirements for foreign brands[6].

Q3: What industries benefit most from Sames powder coating equipment?

A3: Automotive, furniture, appliances, construction, and other industries requiring durable and high-quality coatings[8].

Q4: How does Sames equipment improve productivity?

A4: Through efficient powder transfer, quick color changes, ergonomic design, and durable components that reduce downtime[1][7].

Q5: What kind of after-sales support is available for OEM clients?

A5: Technical support, spare parts supply, and maintenance guidance are provided to ensure smooth operation post-sale[6].

[1] https://www.sames.com/usa/en/ranges-powder.html

[2] https://www.columbiacoatings.com/SAMESKREMLIN

[3] https://www.youtube.com/watch?v=TeL6l-rrtXY

[4] https://shop.cardinalpaint.com/products/910030904-sames-inocart-vt-6m-manual-powder-coating-system

[5] https://icafecompanies.com/powder-coating-sames/

[6] https://kjc.tust.edu.cn/docs/20181012095635354040.xlsx

[7] https://www.youtube.com/watch?v=pPmTAhmU4-Q

[8] https://www.wagner-group.com/cn/%E5%B7%A5%E4%B8%9A/%E4%BA%A7%E5%93%81/%E7%B2%89%E6%9C%AB%E5%96%B7%E6%B6%82/

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.