Content Menu

● Introduction

● What is Small Shop Powder Coating Equipment?

>> Definition and Scope

>> Key Components

● Advantages of Small Shop Powder Coating Equipment

>> Cost-Effectiveness

>> Space Efficiency

>> Ease of Use and Maintenance

>> Versatility

● Types of Small Shop Powder Coating Equipment

>> Mini Powder Coating Systems

>> Electrostatic Powder Coating Machines

>> Turn-Key Powder Coating Systems

● OEM Manufacturing and Design for Small Shop Powder Coating Equipment

>> Customized Solutions for Global Brands

>> Benefits of OEM Partnerships

● Applications of Small Shop Powder Coating Equipment

>> Automotive and Industrial Parts

>> Furniture and Decorative Items

>> Electronics and Appliances

● How to Choose the Right Small Shop Powder Coating Equipment

>> Consider Your Production Scale

>> Powder Compatibility

>> Space and Installation Requirements

>> Budget and ROI

● Maintenance and Operational Tips for Small Shop Powder Coating Equipment

>> Regular Cleaning

>> Calibration and Testing

>> Safety Precautions

● Future Trends in Small Shop Powder Coating Equipment

>> Automation and Smart Controls

>> Eco-Friendly Powders and Processes

>> Modular and Scalable Systems

● Frequently Asked Questions (FAQs)

Introduction

As a leading Chinese manufacturer, supplier, and OEM service provider for powder coating equipment, we specialize in delivering high-quality, customized solutions to global brands, wholesalers, and producers. This comprehensive guide explores the world of small shop powder coating equipment, detailing its benefits, types, applications, and how OEM partnerships can elevate your business. Whether you are a small business owner, hobbyist, or a brand looking to outsource manufacturing, understanding the nuances of small powder coating systems is crucial.

What is Small Shop Powder Coating Equipment?

Definition and Scope

Small shop powder coating equipment refers to compact, efficient powder coating systems designed for small-scale operations such as hobby shops, small businesses, or prototype production lines. These systems are typically more affordable, easier to install, and require less space compared to industrial-scale equipment, making them ideal for startups and OEM manufacturers catering to niche markets[5][1].

Key Components

- Powder Coating Gun: The heart of the system, responsible for electrostatically charging the powder and spraying it onto the substrate[2][4].

- Powder Spray Booth: A contained environment that captures overspray and protects operators.

- Curing Oven: Used to bake the powder coating onto the surface, ensuring durability and finish quality[1][7].

Advantages of Small Shop Powder Coating Equipment

Cost-Effectiveness

Small powder coating machines are significantly less expensive than large industrial systems, making them accessible for small shops and OEMs looking to reduce upfront investment[5].

Space Efficiency

Compact designs allow installation in limited spaces, such as small workshops or home garages, without compromising performance[1][3].

Ease of Use and Maintenance

These systems are designed for quick setup and simple maintenance, facilitating fast production cycles and minimal downtime[5].

Versatility

Small shop powder coating equipment can handle a variety of substrates and powder types, enabling manufacturers to serve diverse customer needs, from automotive parts to decorative items[5][9].

Types of Small Shop Powder Coating Equipment

Mini Powder Coating Systems

Self-contained units that do not require an external power source, ideal for beginners and hobbyists. These systems offer portability and ease of use[5].

Electrostatic Powder Coating Machines

These machines use electrostatic charges to attract powder particles to the workpiece. They are suitable for small businesses and provide precise control over powder flow and coating thickness[2][5].

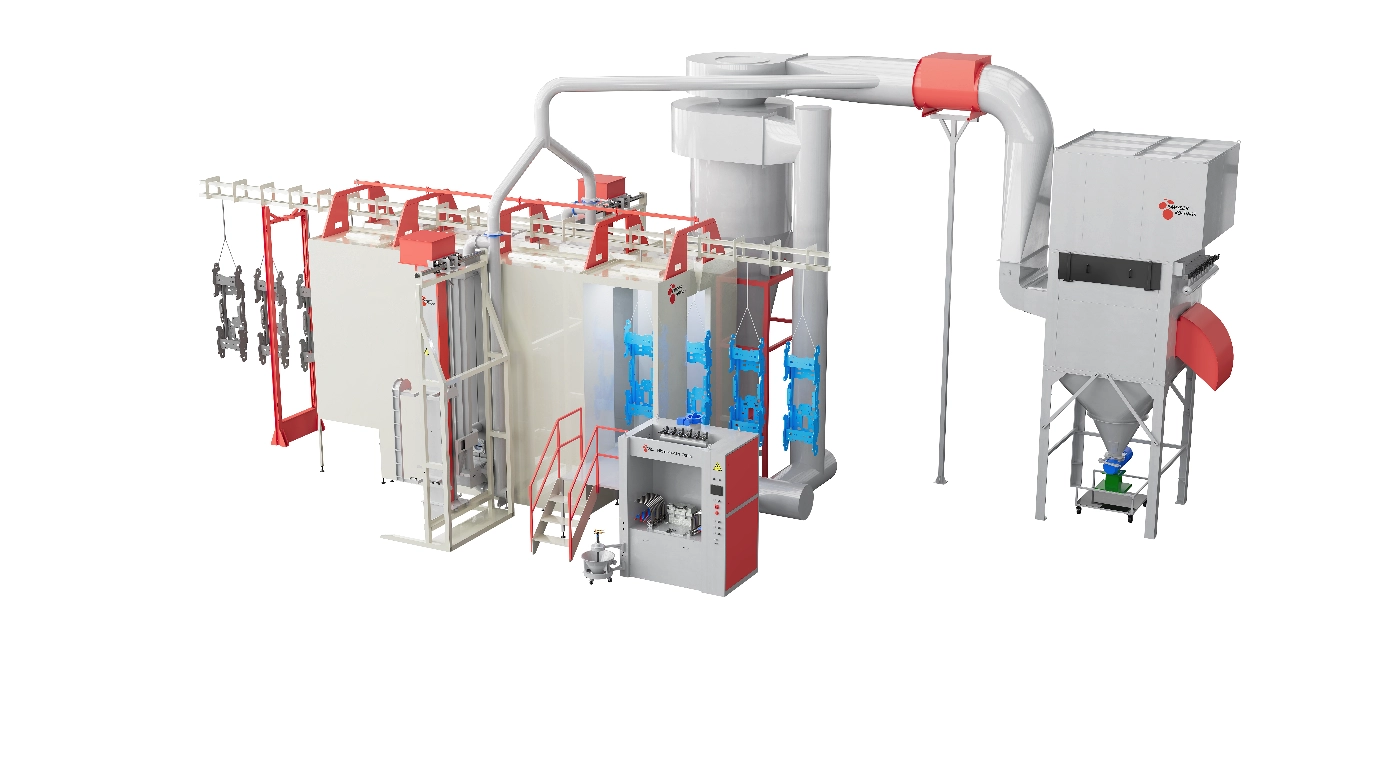

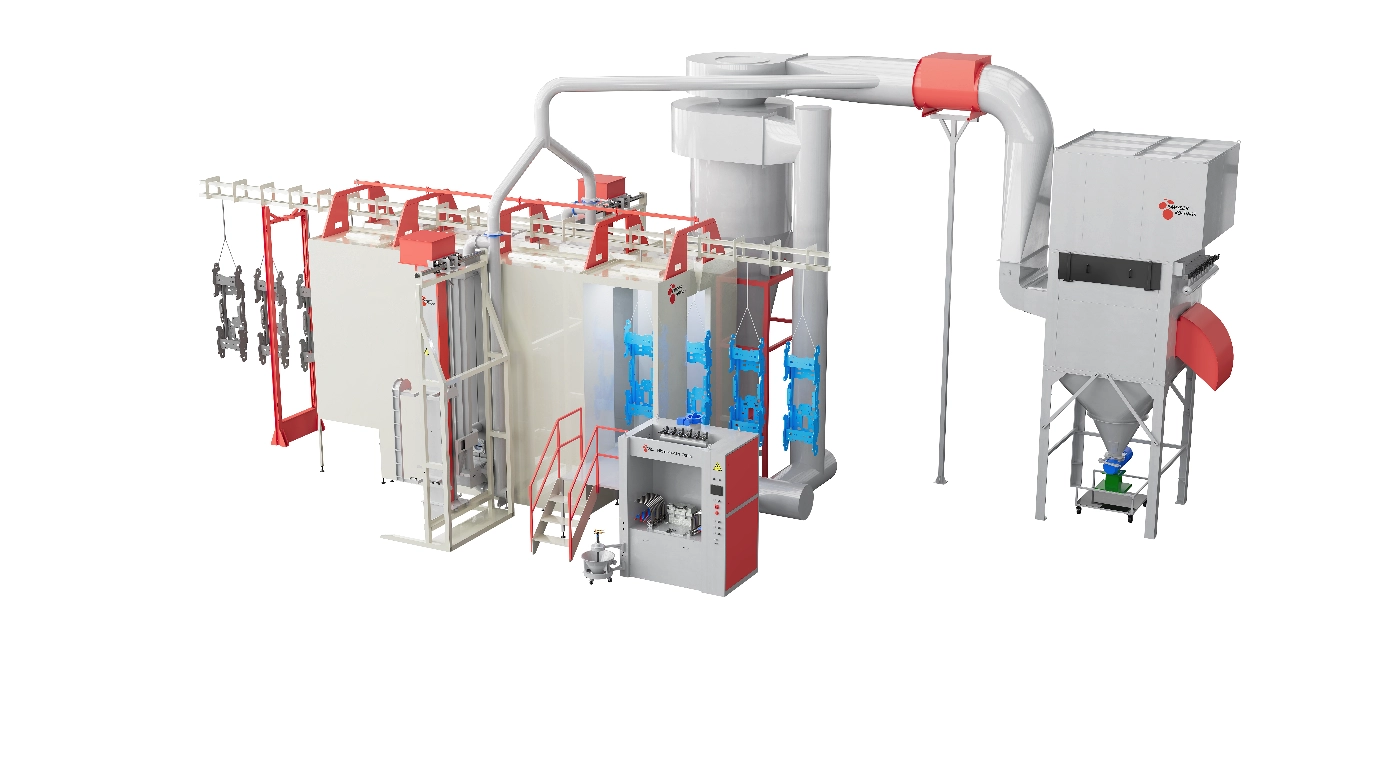

Turn-Key Powder Coating Systems

Complete packages including powder guns, spray booths, and ovens, designed for small custom shops and home hobbyists. These systems are industrial-strength yet affordable, offering high performance comparable to larger systems[1].

OEM Manufacturing and Design for Small Shop Powder Coating Equipment

Customized Solutions for Global Brands

As an experienced OEM manufacturer, we provide tailored powder coating equipment solutions that meet the specific requirements of international brands, wholesalers, and production companies. Our expertise includes design, production, and supply chain management to ensure quality and consistency[6].

Benefits of OEM Partnerships

- Access to advanced manufacturing technologies and quality control.

- Cost savings through economies of scale.

- Flexibility in product customization and branding.

- Reliable supply and timely delivery.

Applications of Small Shop Powder Coating Equipment

Automotive and Industrial Parts

Small powder coating equipment is widely used for coating automotive components, machinery parts, and tools, providing durable and corrosion-resistant finishes[9].

Furniture and Decorative Items

Compact systems enable coating of metal furniture, home décor, and art pieces with various textures and colors[6].

Electronics and Appliances

Small shops can efficiently coat electronic housings and appliance parts, enhancing aesthetic appeal and protection[6].

How to Choose the Right Small Shop Powder Coating Equipment

Consider Your Production Scale

Evaluate your typical batch size and production volume to select a system that balances capacity and cost[5].

Powder Compatibility

Ensure the equipment supports the types of powders you intend to use, such as epoxy, polyester, or hybrid powders[9].

Space and Installation Requirements

Measure your available workspace and choose equipment with appropriate dimensions and installation needs[1][3].

Budget and ROI

Calculate the total cost of ownership, including maintenance and consumables, to ensure a good return on investment[5].

Maintenance and Operational Tips for Small Shop Powder Coating Equipment

Regular Cleaning

Clean spray guns, booths, and ovens frequently to prevent powder buildup and ensure consistent coating quality[4].

Calibration and Testing

Periodically calibrate equipment settings such as voltage and powder flow to maintain optimal performance[2].

Safety Precautions

Use proper ventilation and personal protective equipment to safeguard operators from powder inhalation and electrical hazards[1].

Future Trends in Small Shop Powder Coating Equipment

Automation and Smart Controls

Integration of digital controls and automation is making small systems more efficient and user-friendly[7].

Eco-Friendly Powders and Processes

Development of low-VOC and recyclable powders aligns with global sustainability goals[9].

Modular and Scalable Systems

Manufacturers are designing modular equipment that can be easily upgraded or expanded as business grows[5].

Frequently Asked Questions (FAQs)

Q1: What is the main difference between small shop powder coating equipment and industrial systems?

A1: Small shop equipment is more compact, affordable, and easier to operate, designed for lower volume production compared to large industrial systems[1][5].

Q2: Can small shop powder coating equipment handle multiple powder types?

A2: Yes, most small systems are compatible with various powder formulations including epoxy, polyester, and hybrids[9].

Q3: How long does it take to cure powder coatings in a small shop oven?

A3: Typically, curing times range from 10 to 30 minutes depending on the powder type and oven temperature settings[1].

Q4: Is OEM customization available for small shop powder coating equipment?

A4: Yes, OEM services include design customization, branding, and specification adjustments to meet client needs[6].

Q5: What maintenance is required for small powder coating machines?

A5: Regular cleaning, calibration, and inspection of components like spray guns and ovens are essential to maintain performance[4].

[1] https://www.columbiacoatings.com/products/equipment/turn-key-powder-system

[2] https://www.powdercoatpro.com/product/powder-coating-kit-80kv-powder-coat-gun-home-small-business-powder-coating-system/

[3] https://www.eastwood.com/powder-coating.html

[4] https://www.colopowdercoatshop.com/products.html

[5] https://ems-powdercoating.com/small-powder-coating-machine/

[6] https://kjc.tust.edu.cn/docs/20181012095635354040.xlsx

[7] https://reliantfinishingsystems.com

[8] https://digital.bnpmedia.com/publication/?i=515645&p=43&pp=1&view=issueViewer

[9] https://www.wagner-group.com/cn/%E5%B7%A5%E4%B8%9A/%E4%BA%A7%E5%93%81/%E7%B2%89%E6%9C%AB%E5%96%B7%E6%B6%82/

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.